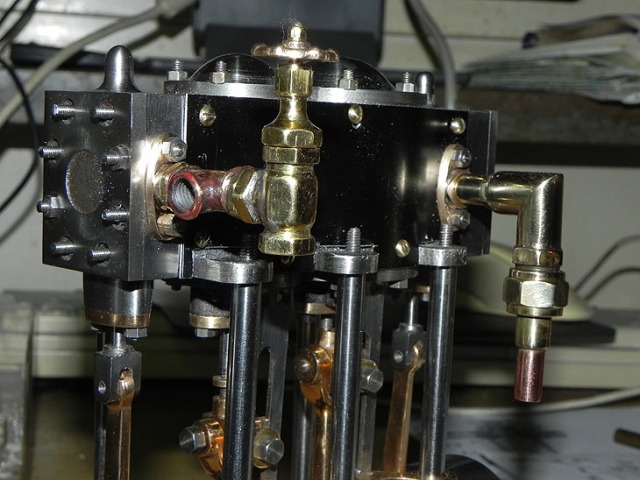

Steam Chests

Hello Ladeys and Gentlemen.

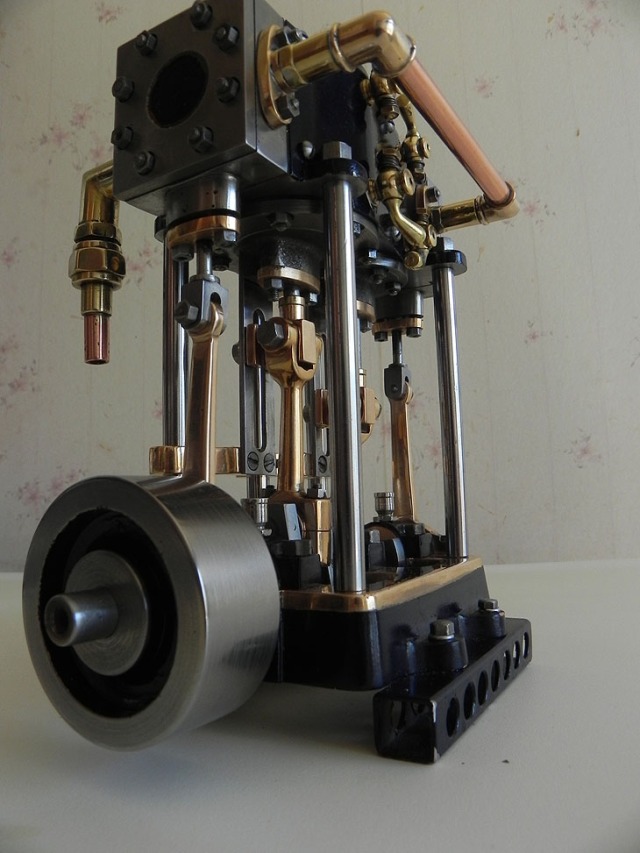

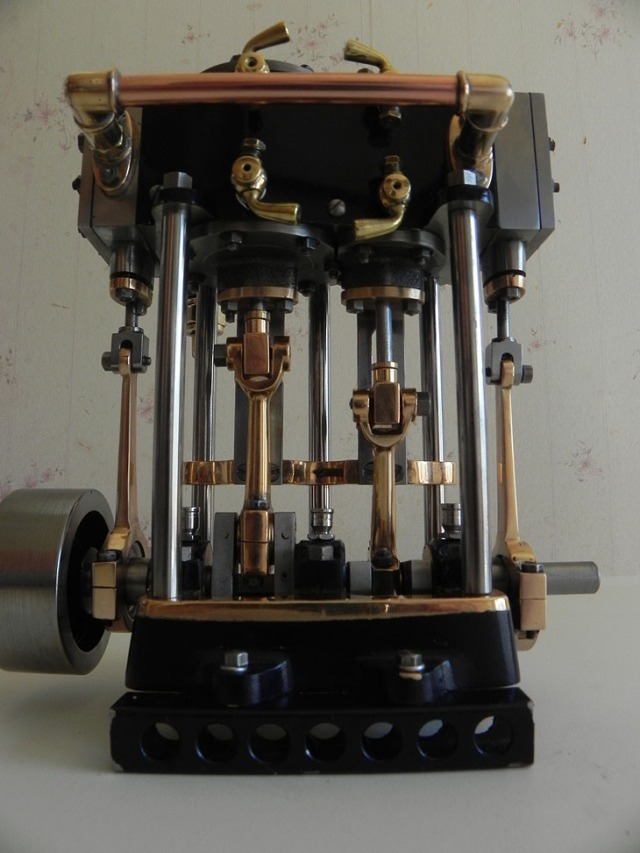

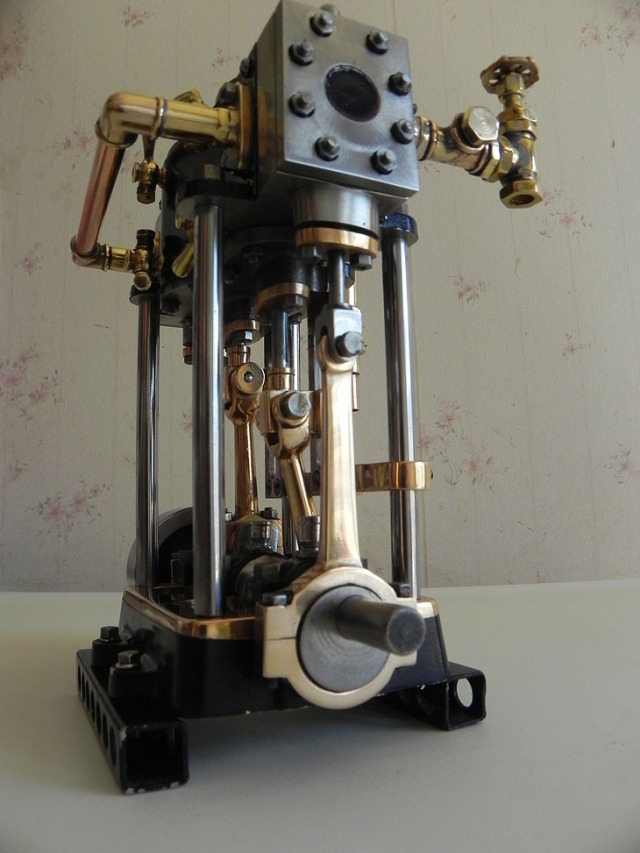

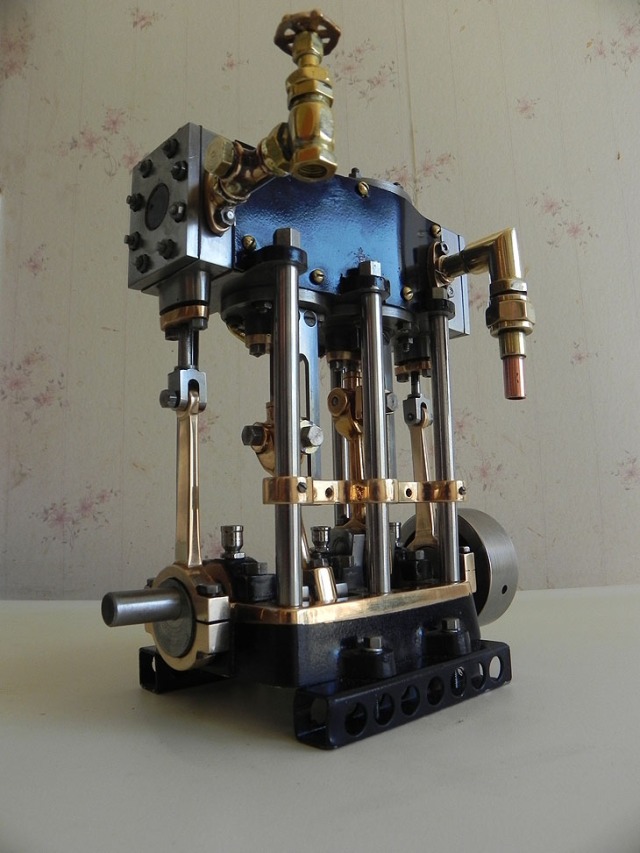

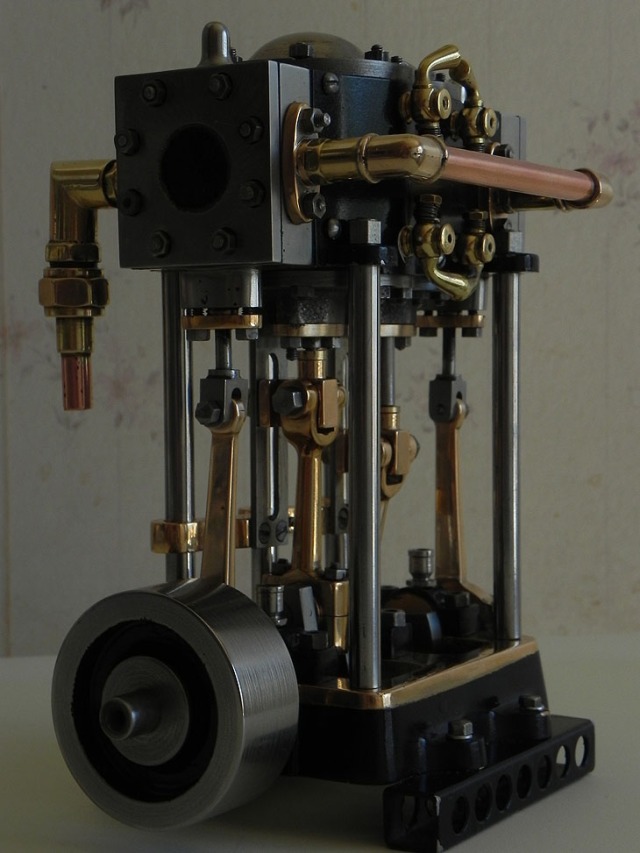

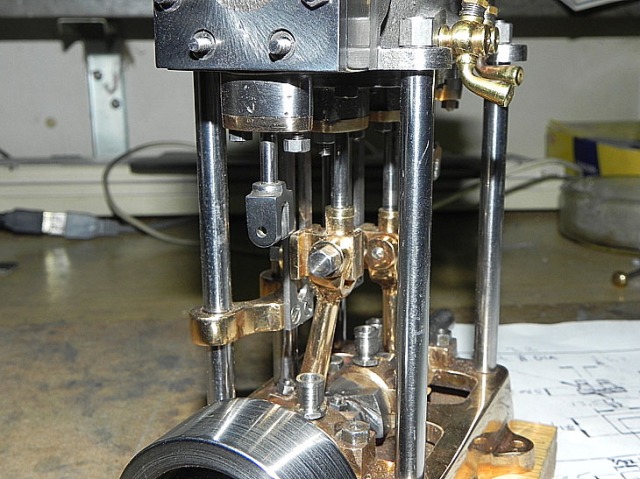

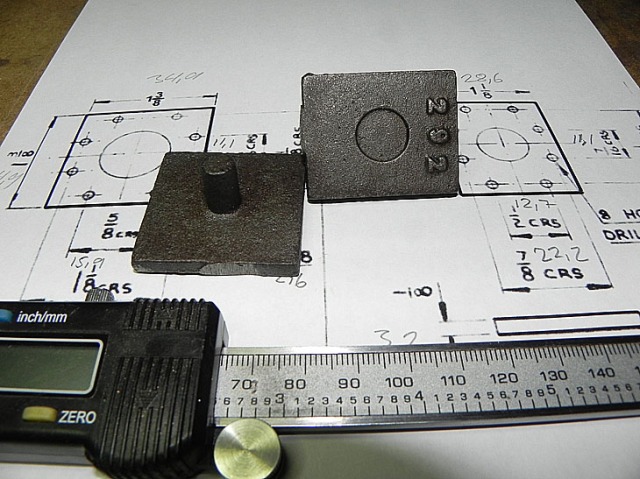

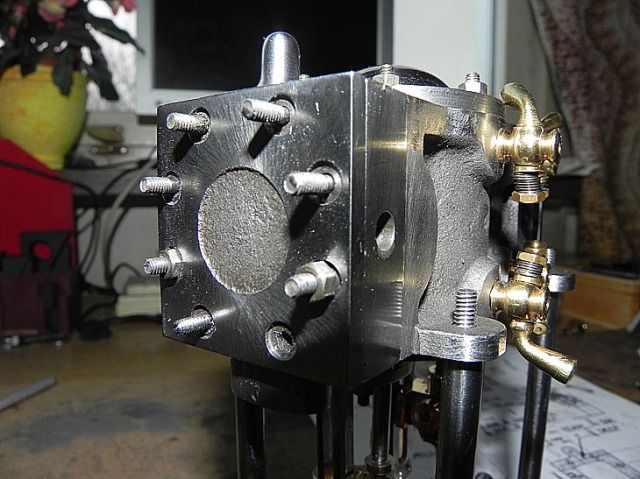

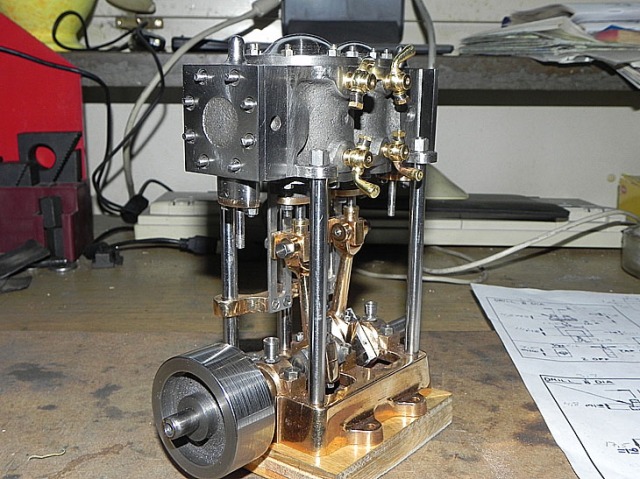

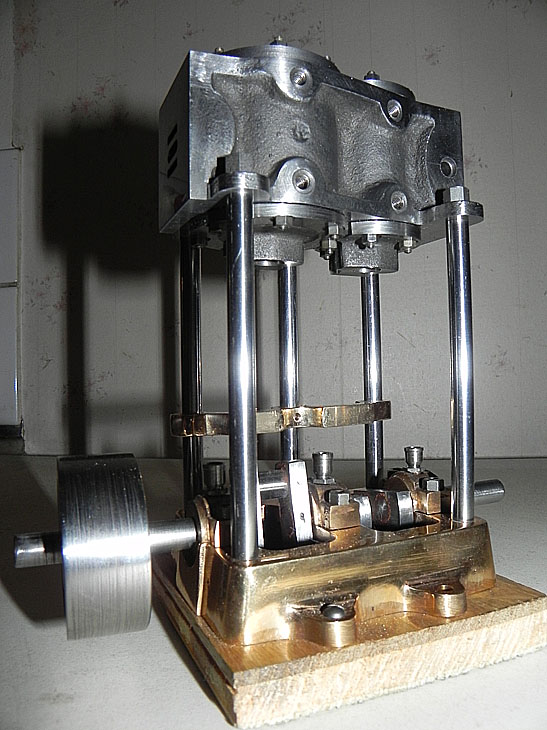

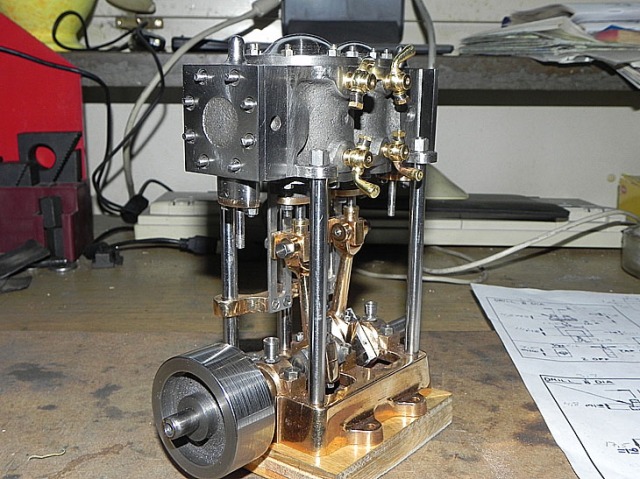

Now it’s time to take care of the steam chest. This is a very important piece of the steam engine, it’s truly the heart of the steam engine.

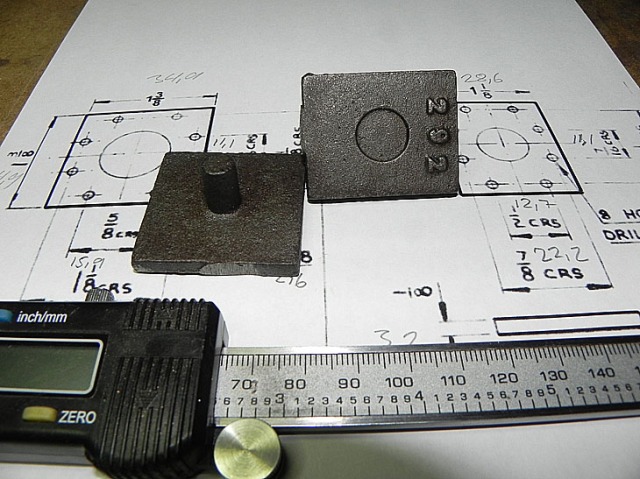

I’ll begin with the cover. The cover has a spigot on the backside so it’s very easy to set up in the lathe.

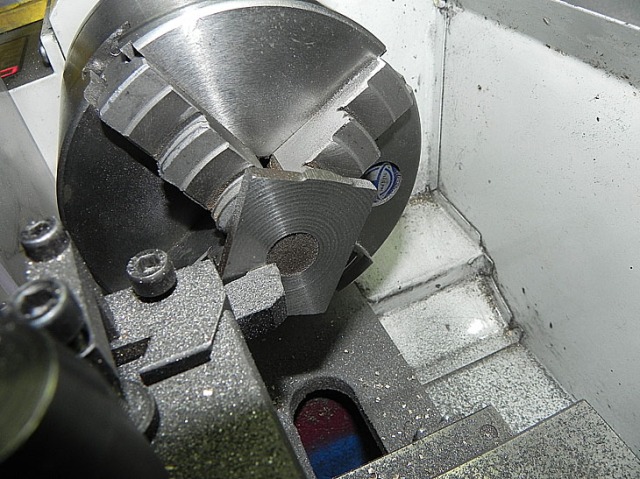

Here I have set up the cover in my lathe for removing the cast skins.

After that I move the cover to my mill so I can mill the side in square.

Then with a hacksaw I cut of the spigot.

Then flatten the backside.

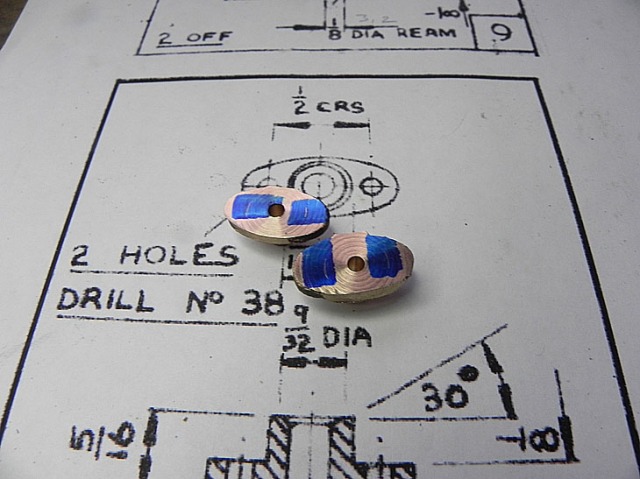

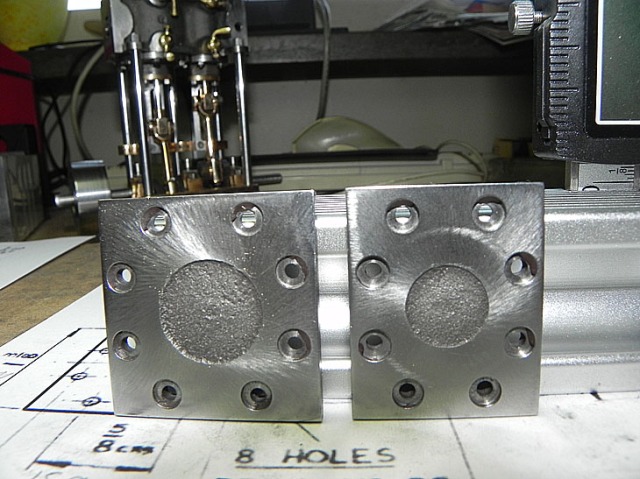

Now I have to mark out for all holes…

… and drilled the holes and countersink the holes.

I feel quite pleased with the result.

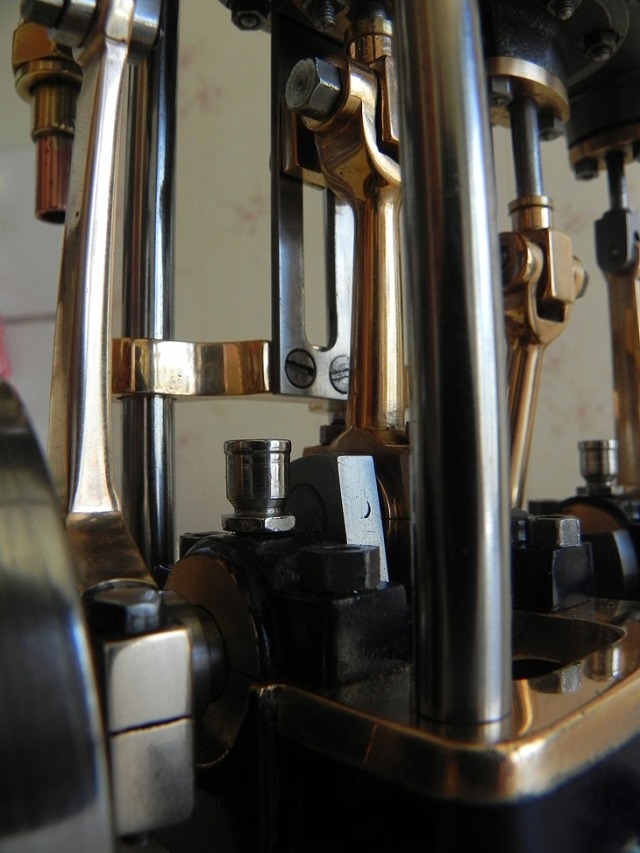

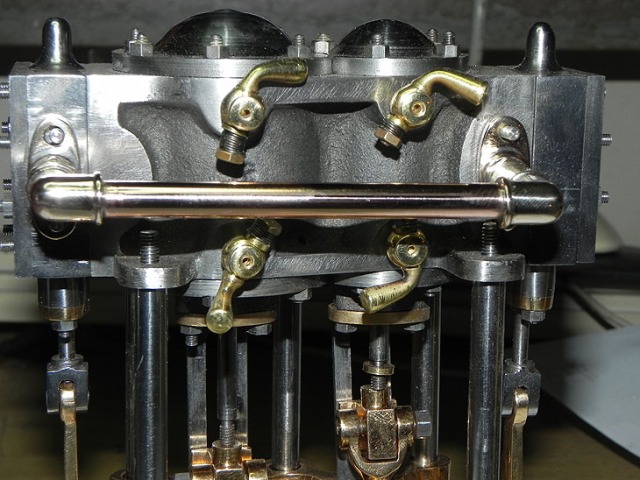

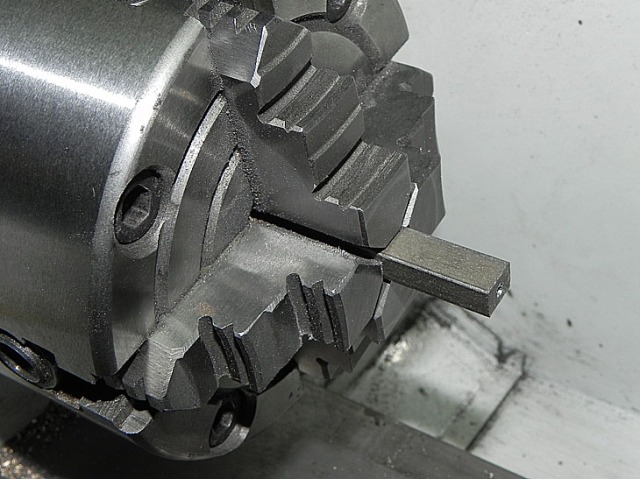

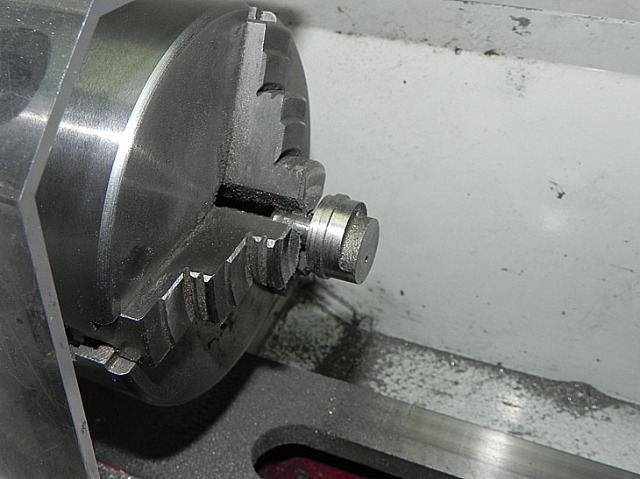

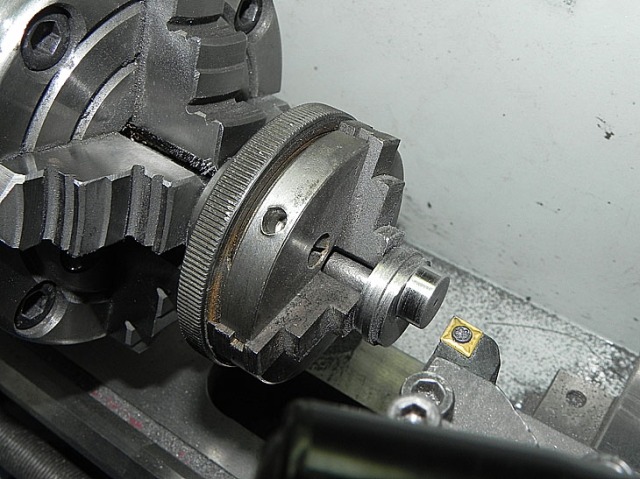

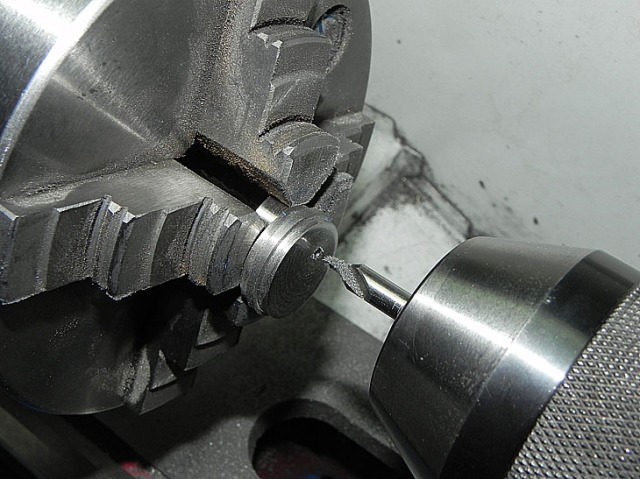

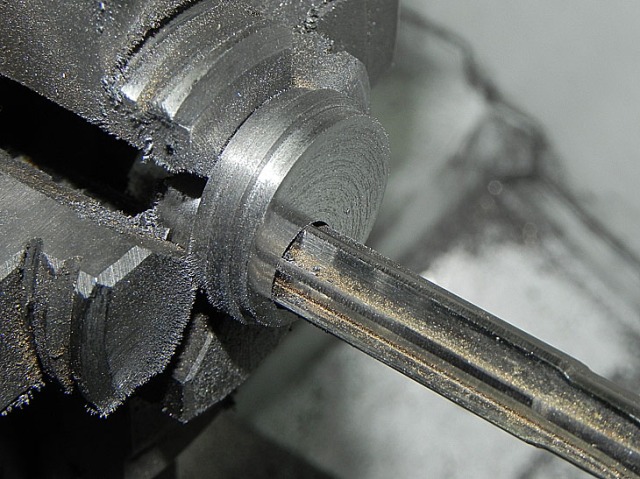

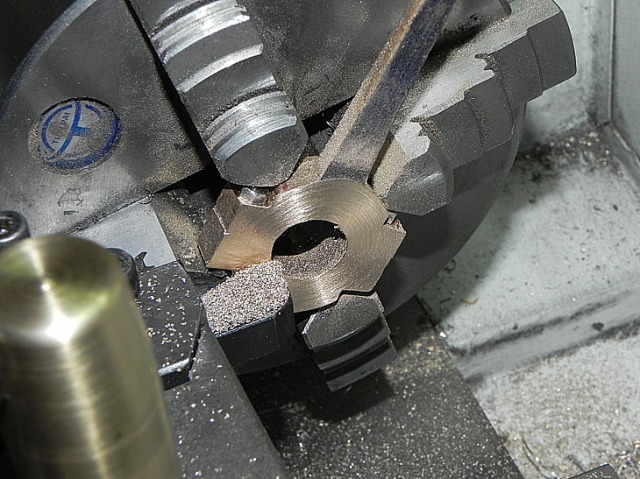

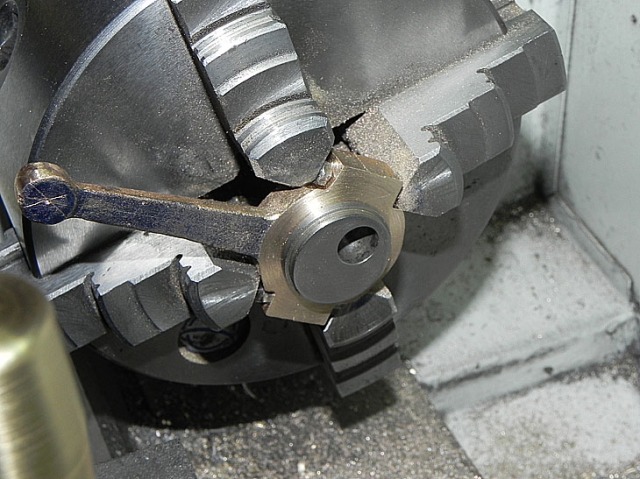

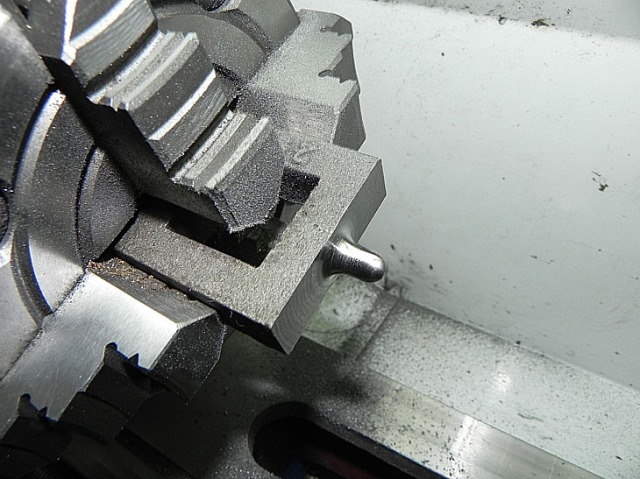

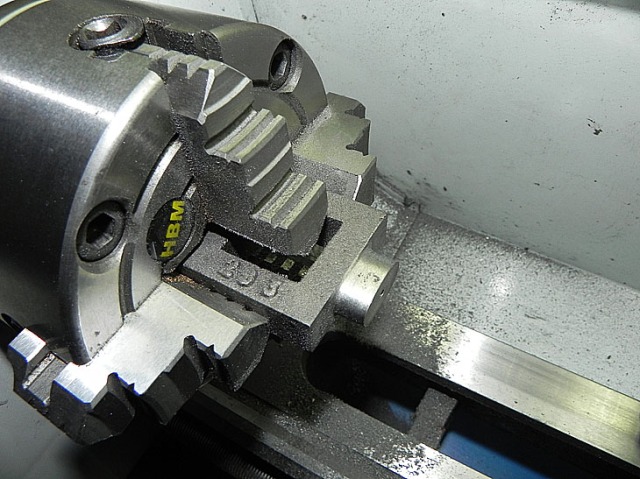

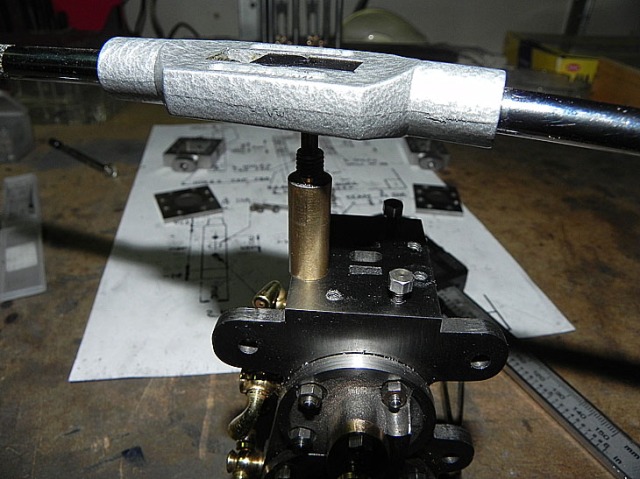

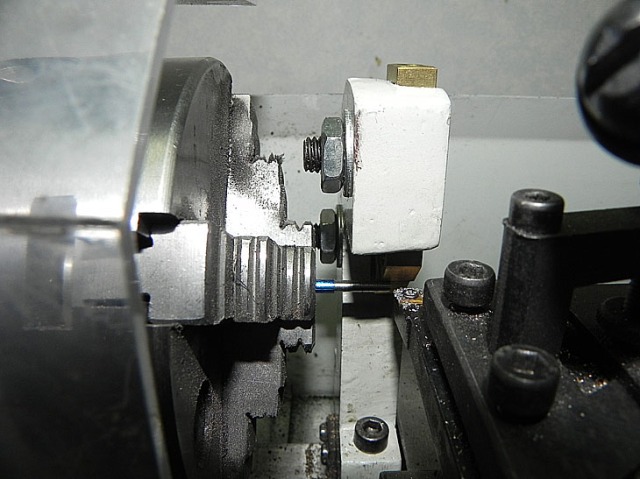

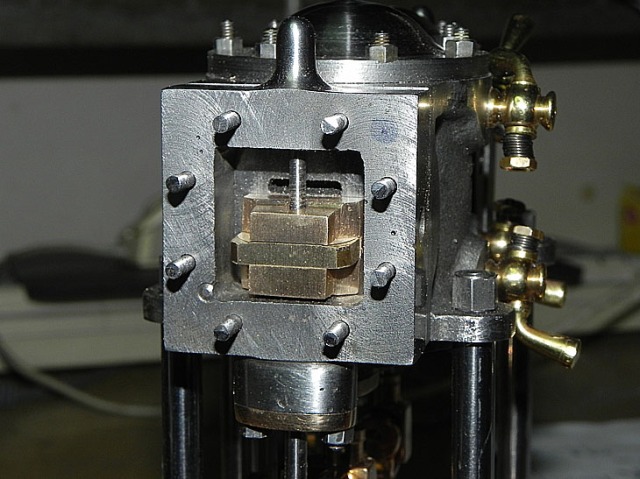

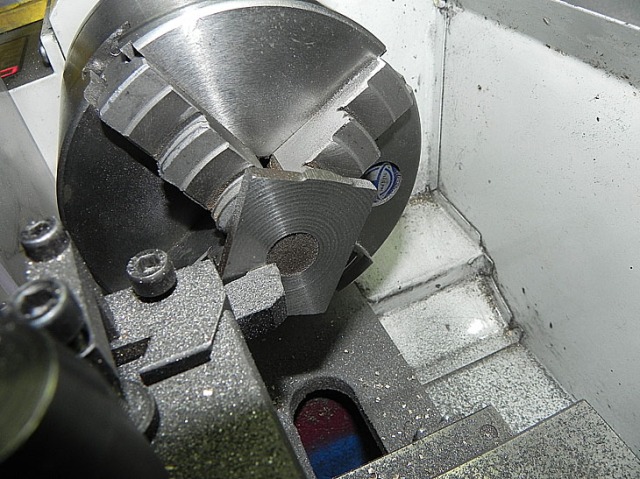

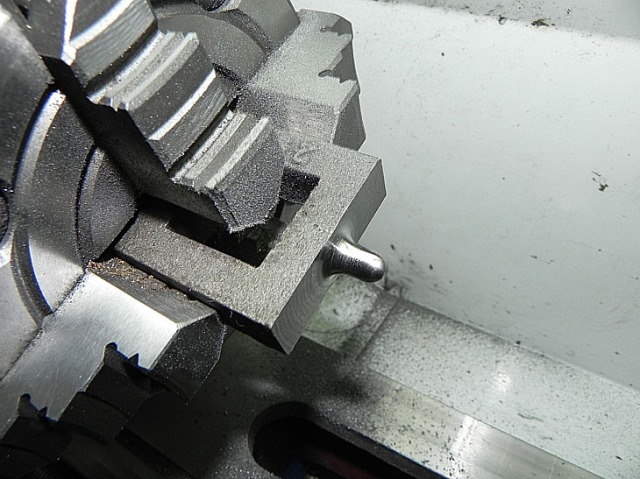

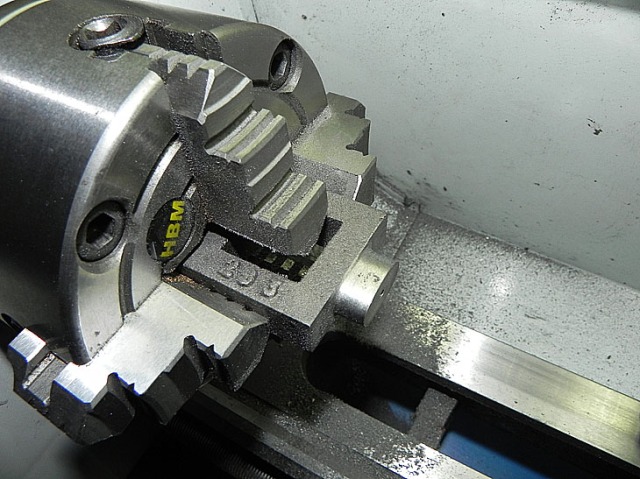

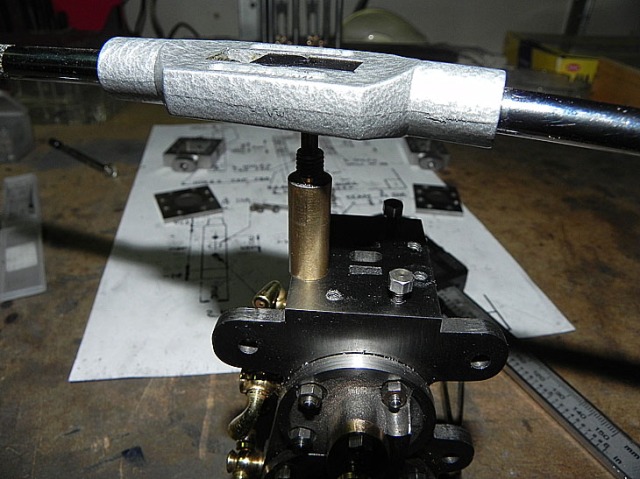

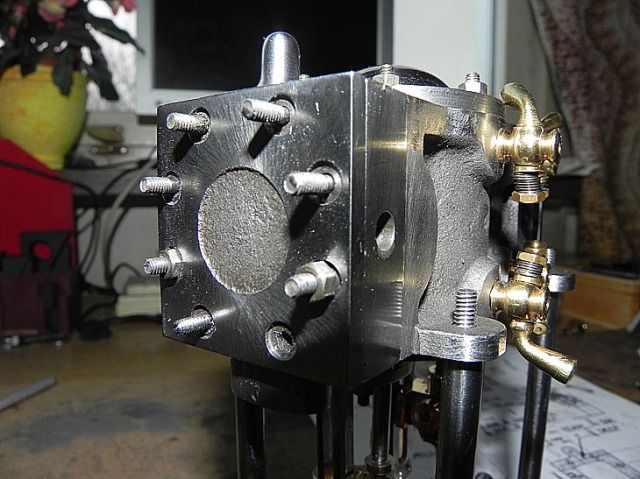

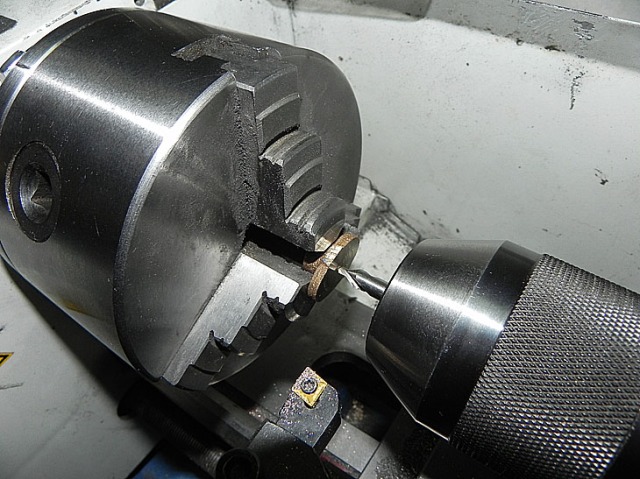

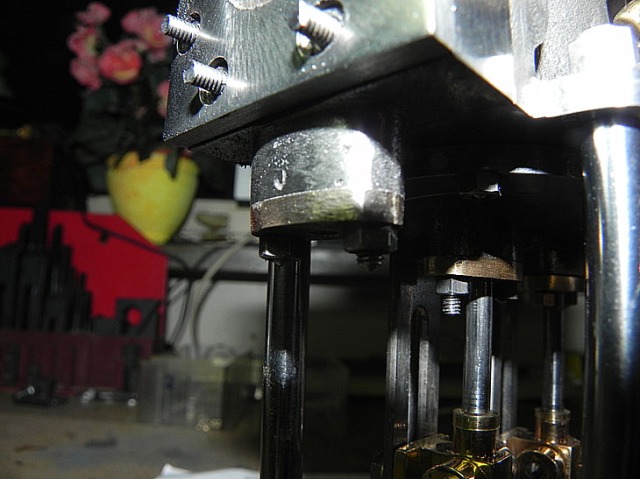

I’ll continue with the steam chests. In the lathe I set up the steam chest in a four jaw chuck and took some turn on the top making the valve rod guide…

… and the bottom for the packing gland.

With a good fill I smooth the packing gland.

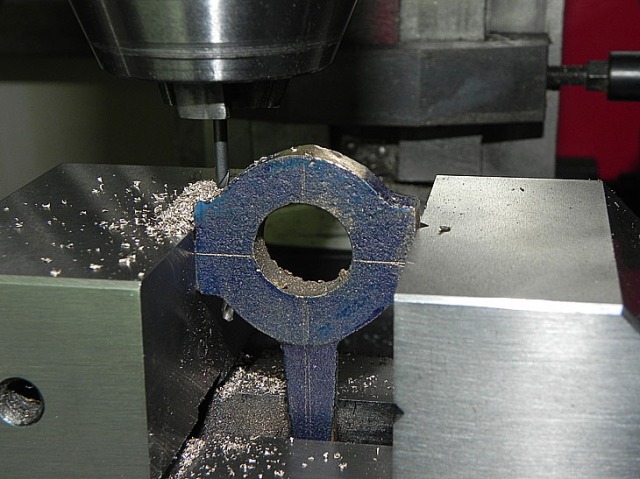

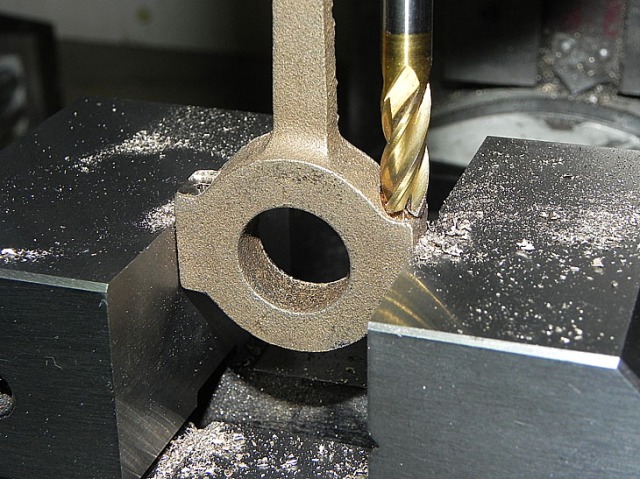

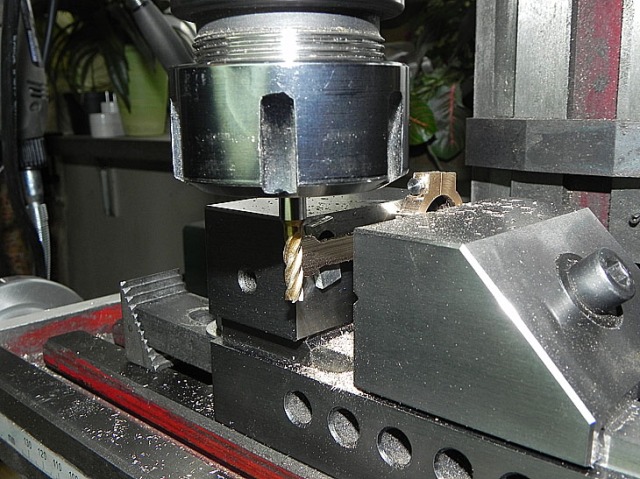

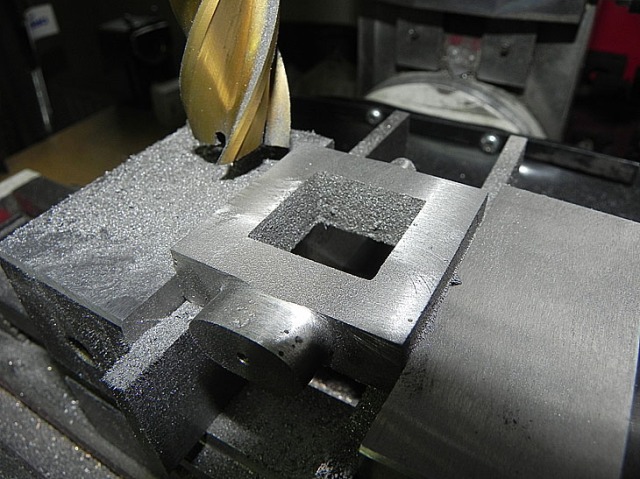

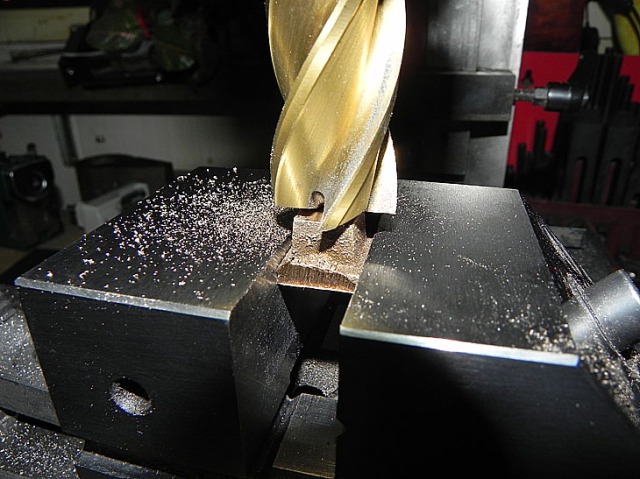

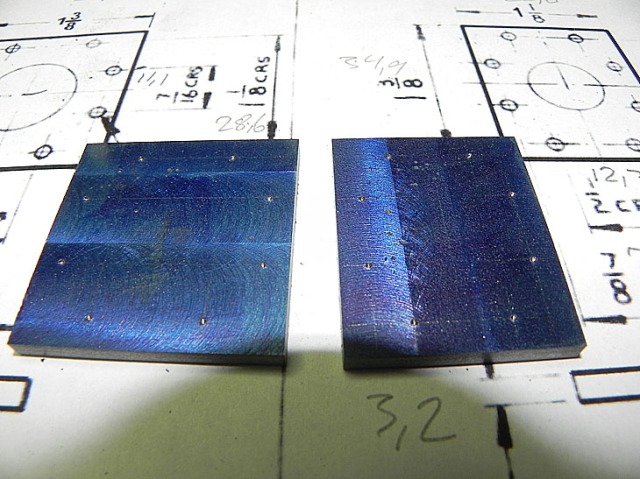

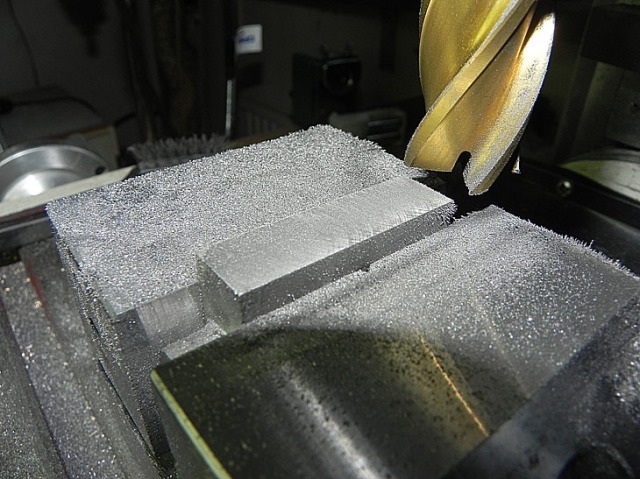

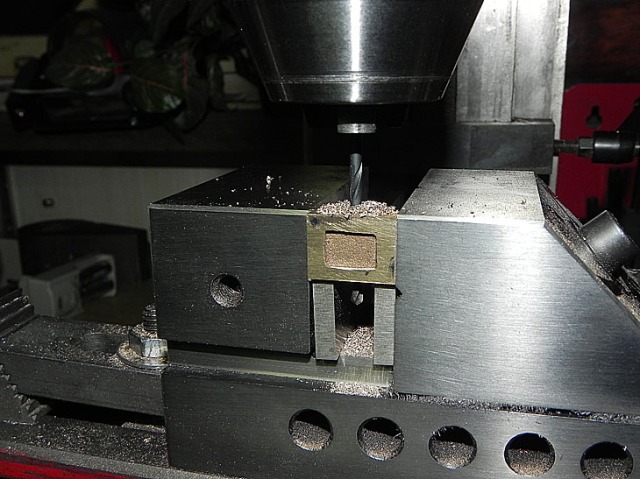

Moving over to the mill for milling both sides to the steam chest…

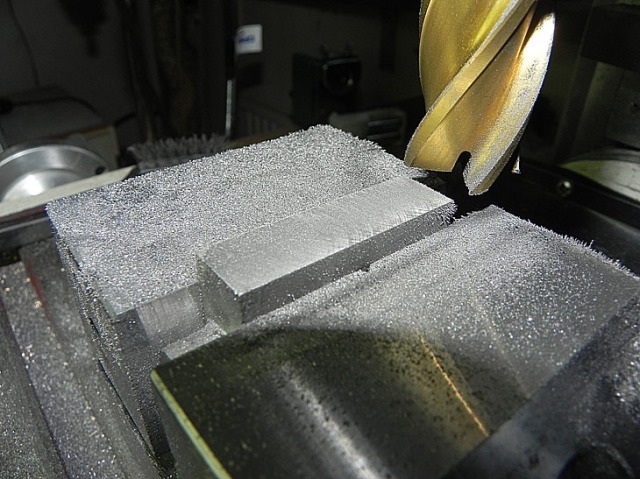

Then I milled both sides…

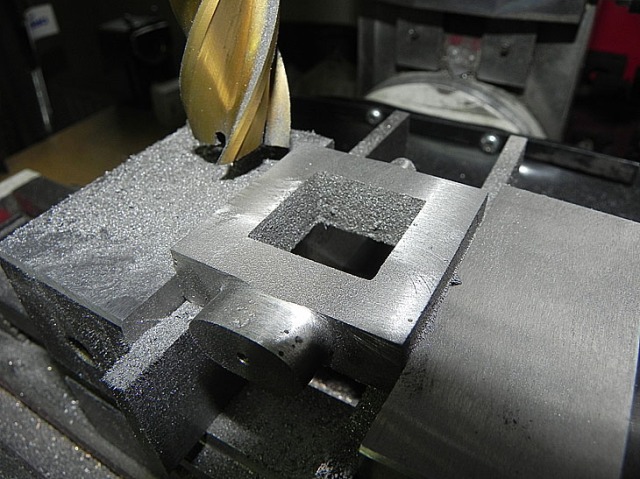

… and the insides as well.

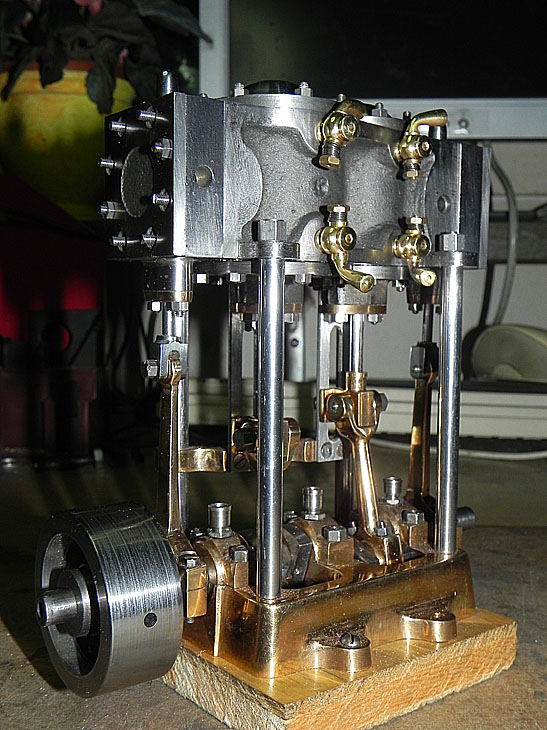

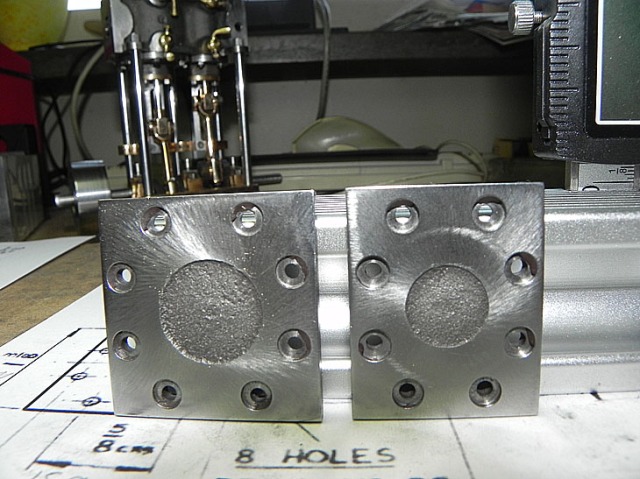

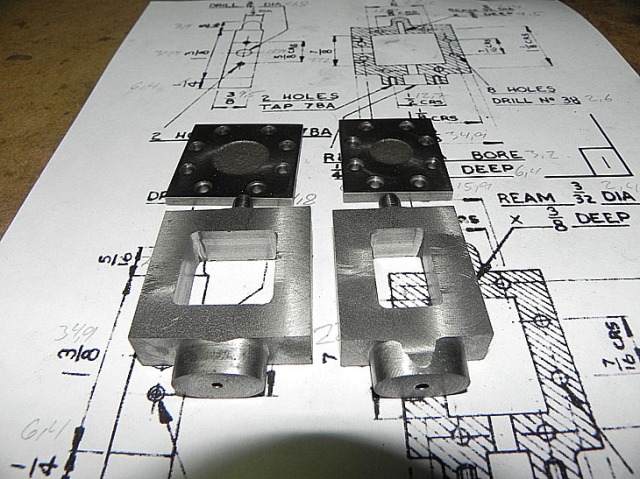

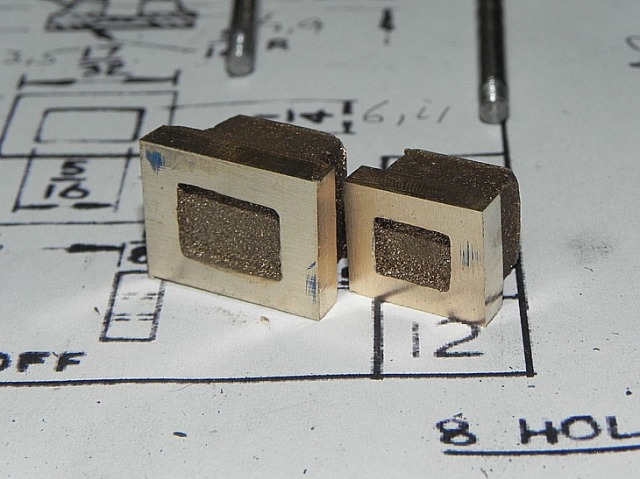

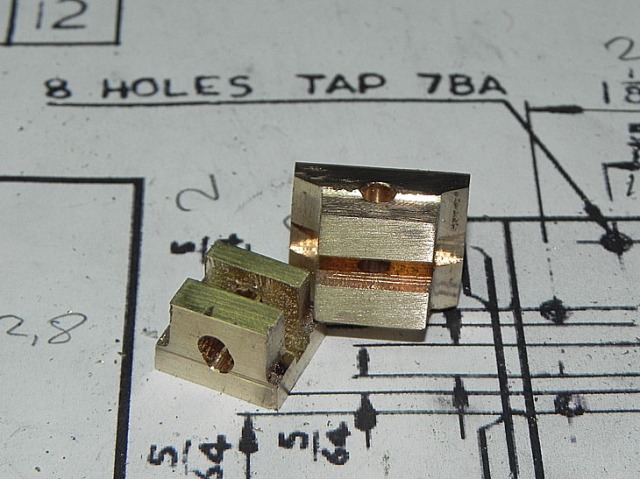

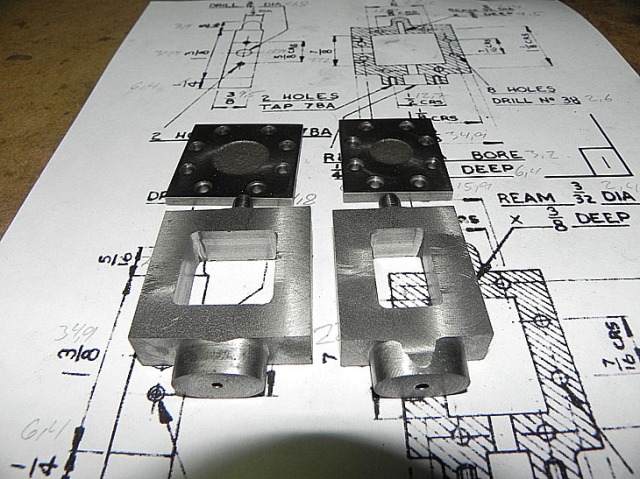

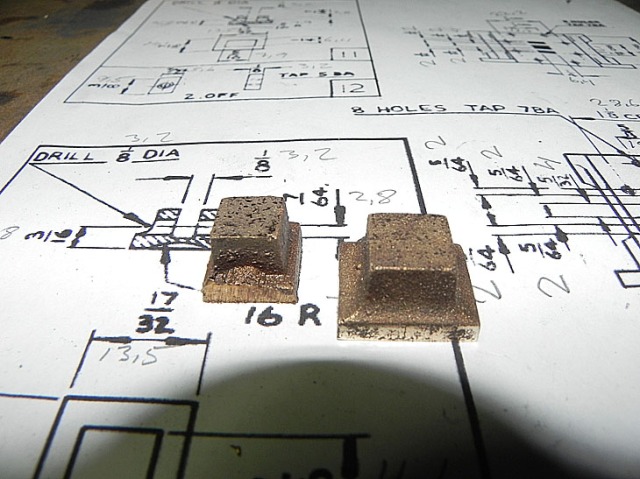

And now I have four pieces so far.

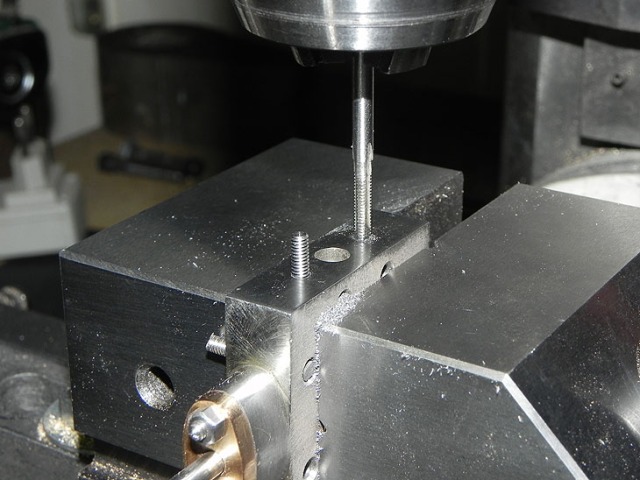

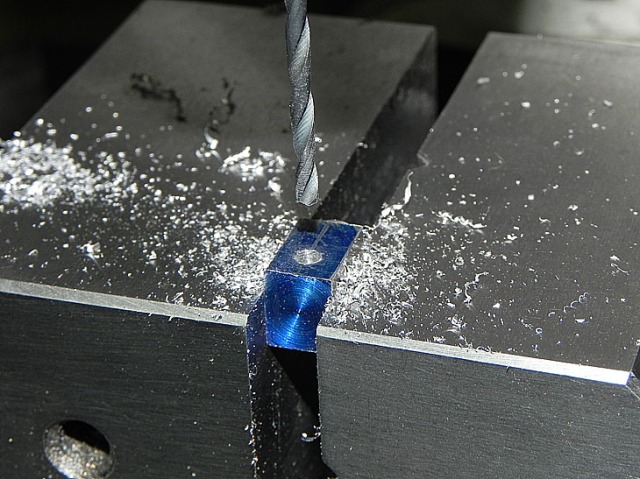

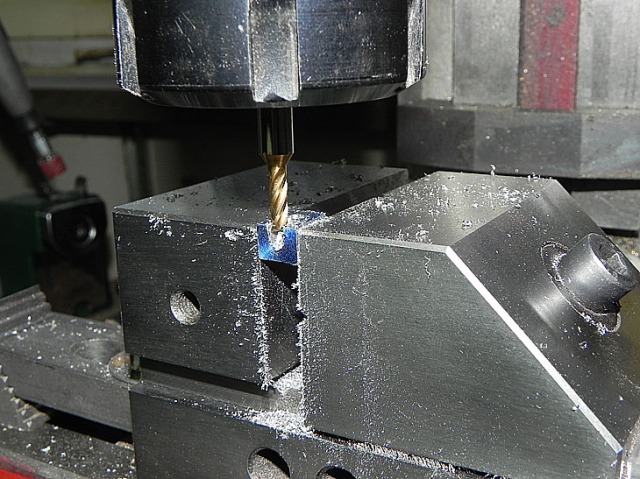

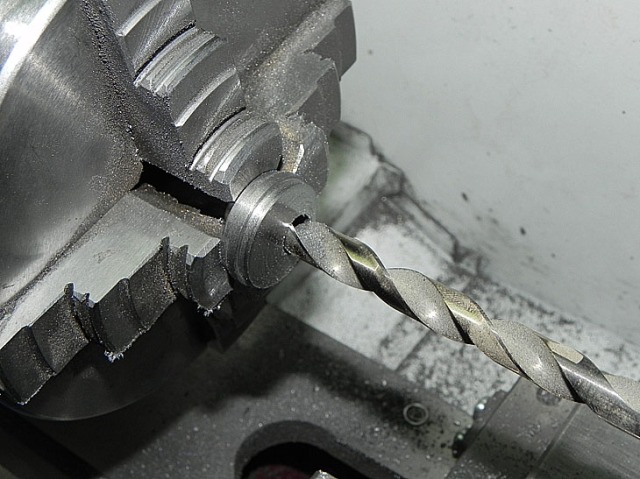

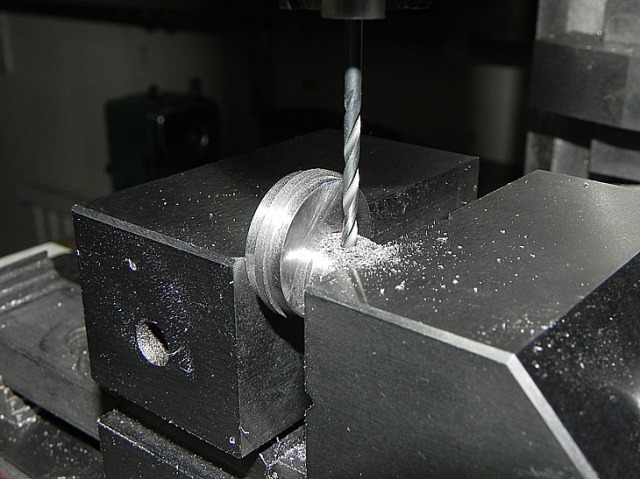

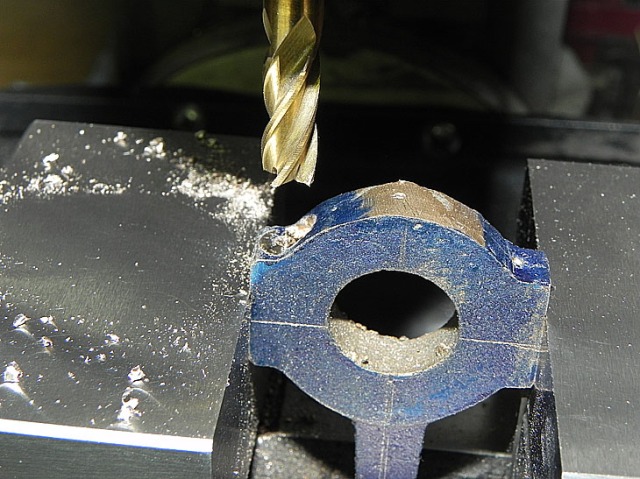

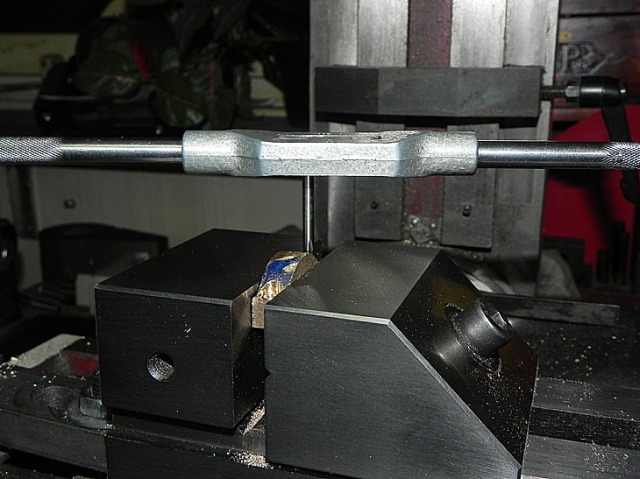

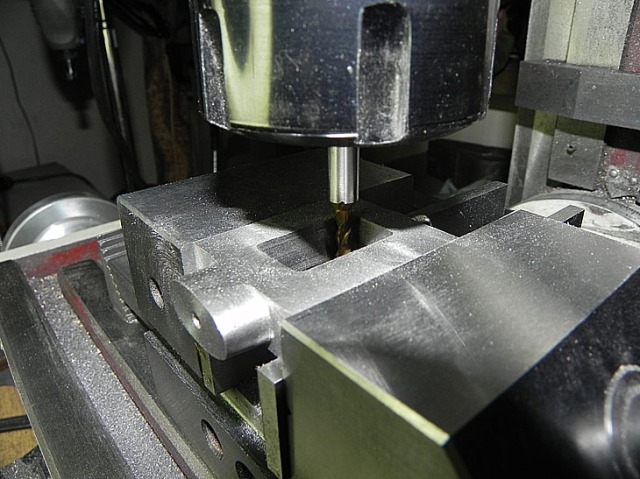

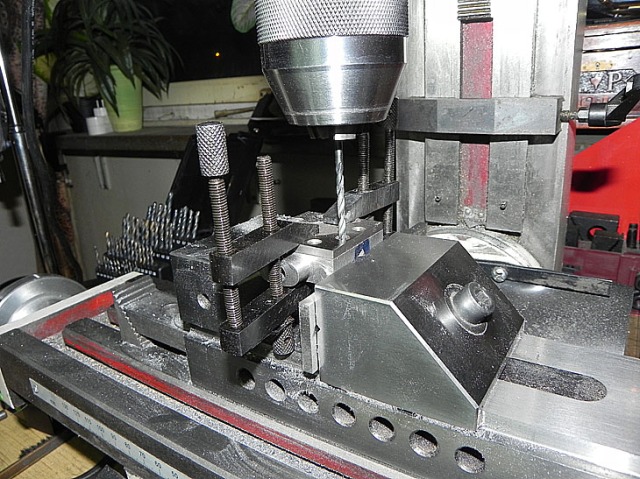

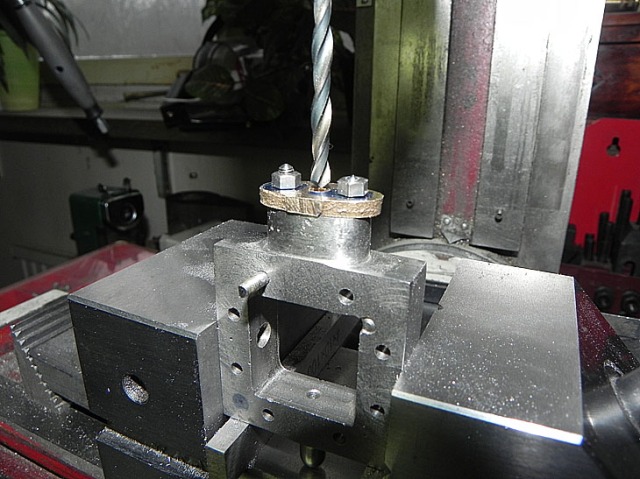

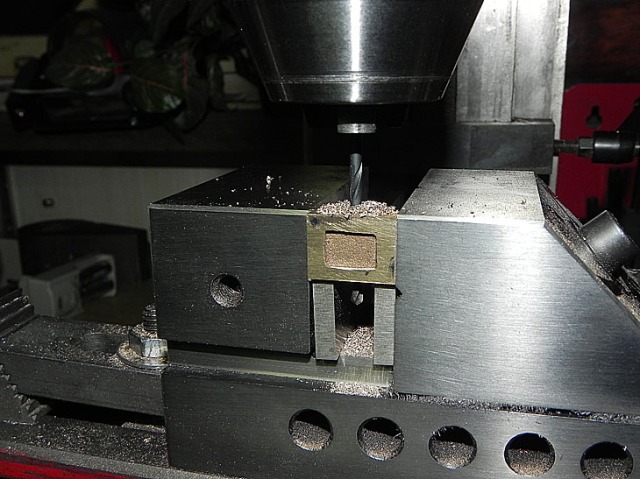

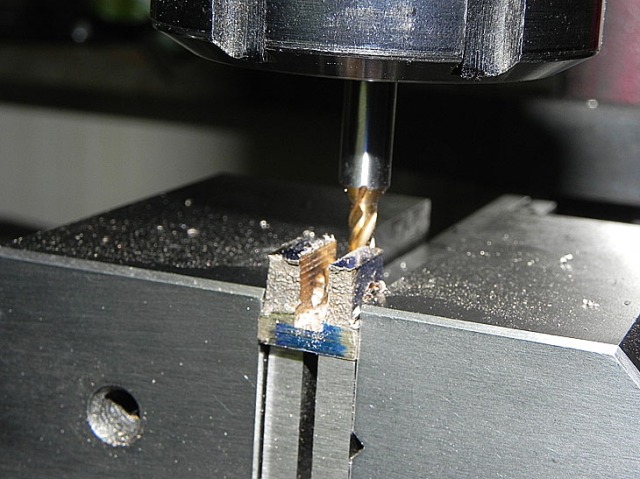

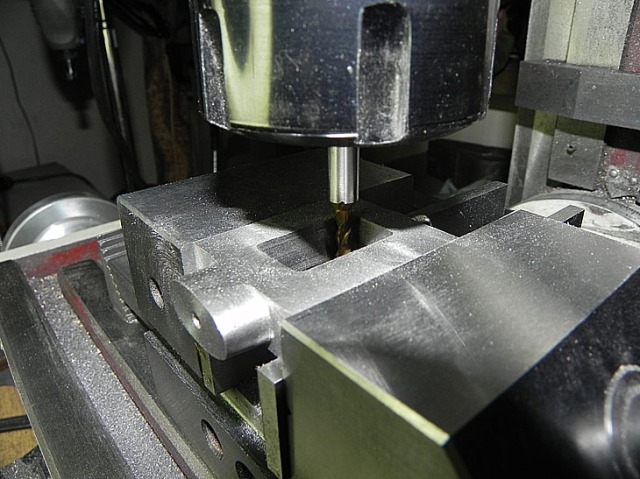

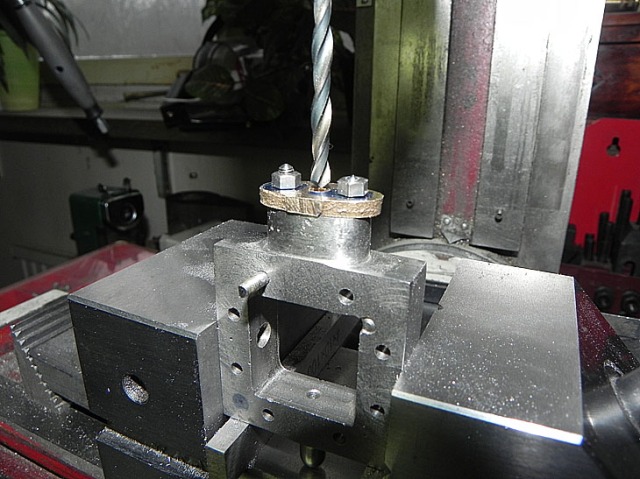

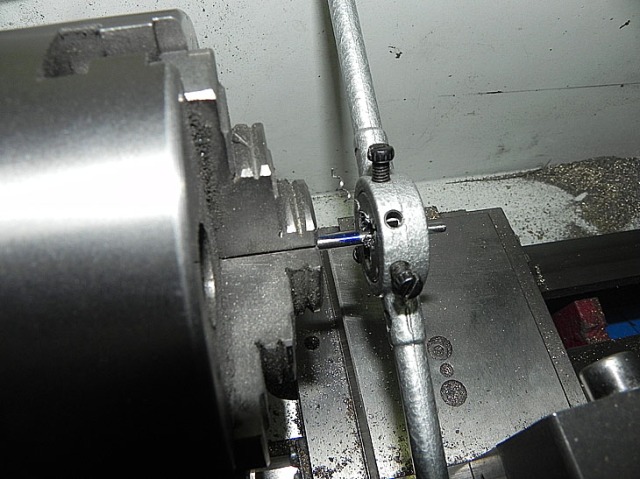

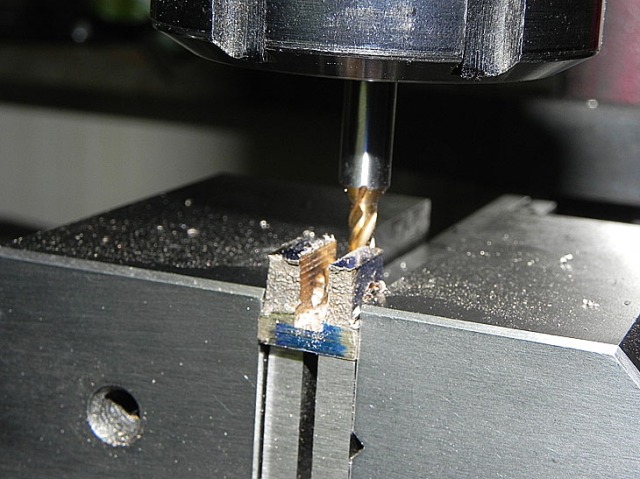

Next, drilling the holes for the valve rod guide…

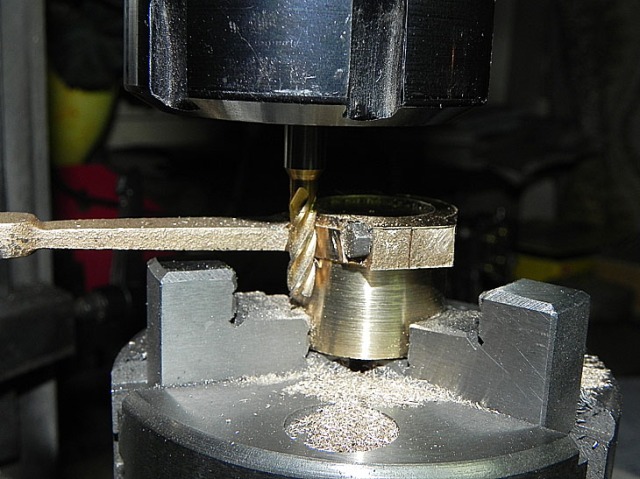

…and then using an end mill for the packing gland.

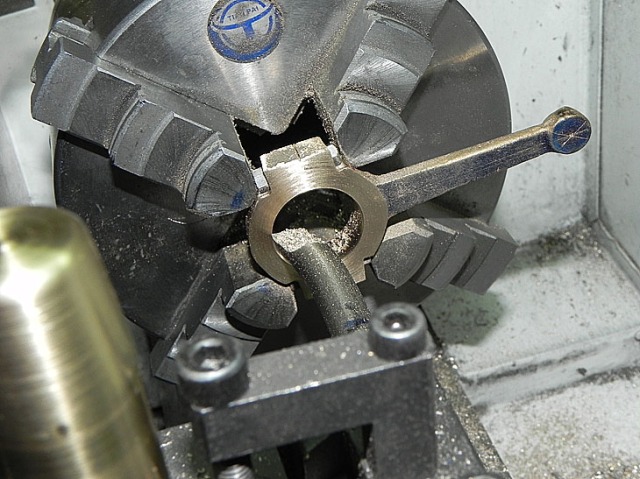

After that I drilled the hole for the steam inlet.

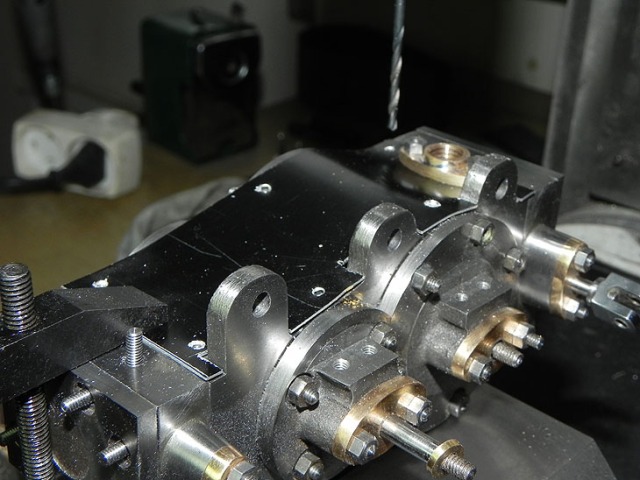

A new setup so I could drill the hole into the steam chest.

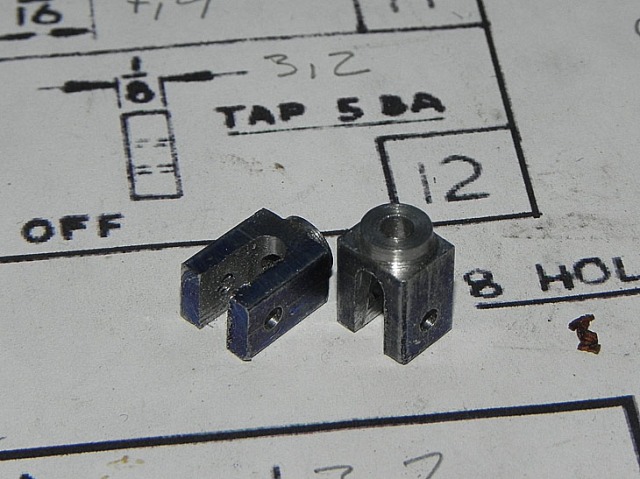

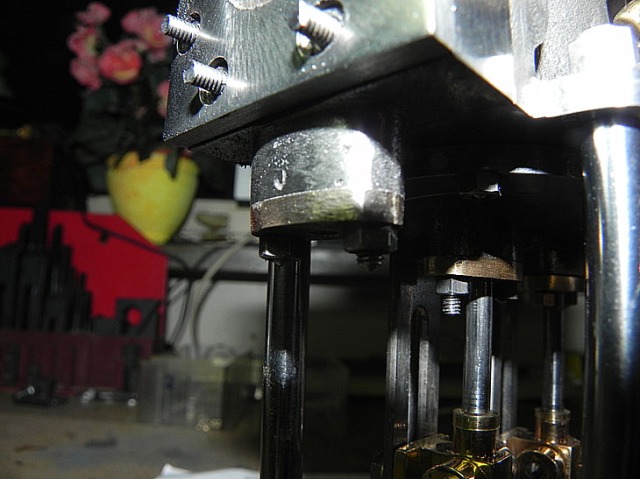

After two holes I’ll use bolt and nuts to hold the two pieces together.

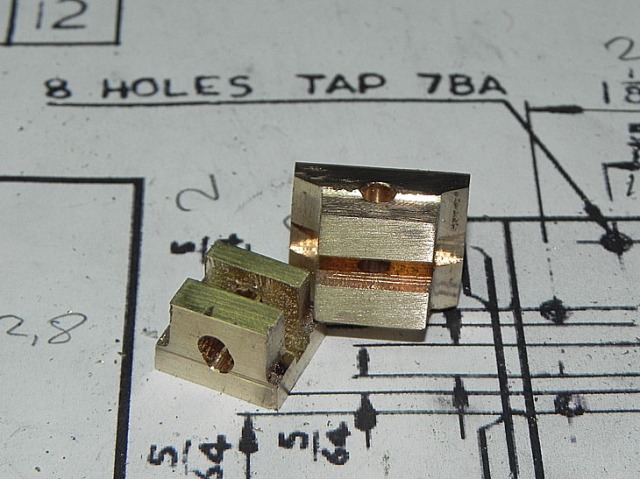

And here we go.

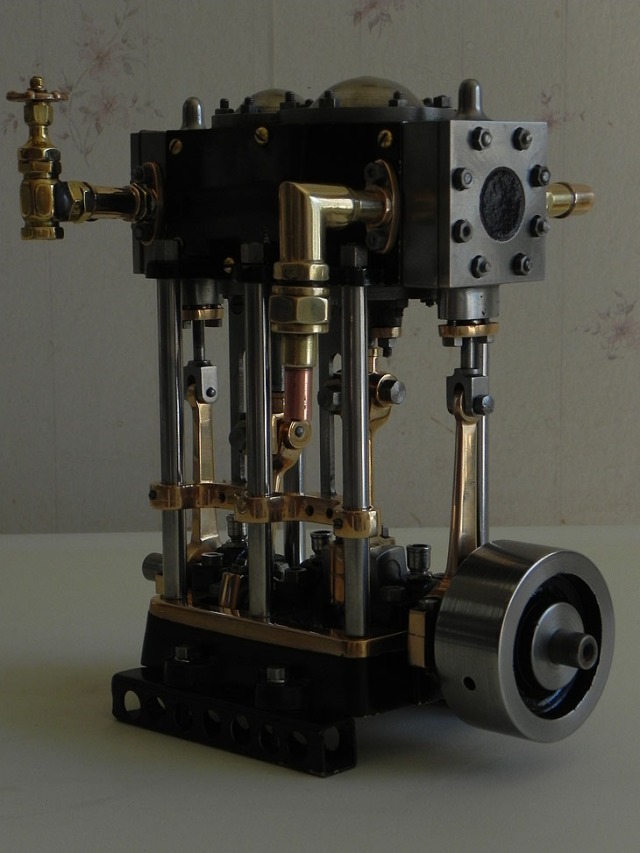

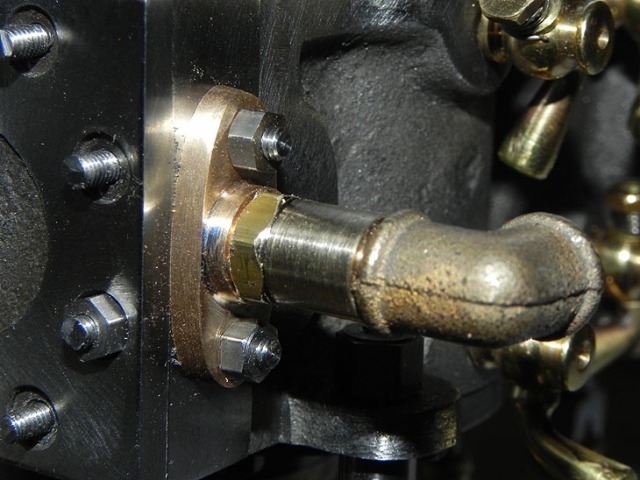

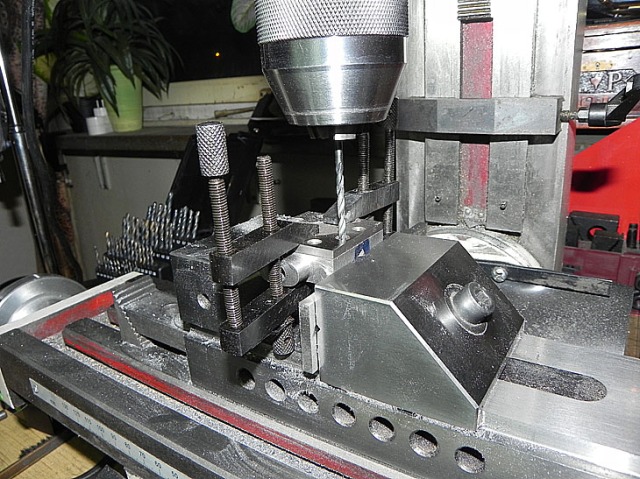

Then, using the cover I drilled the holes in the cylinder block…

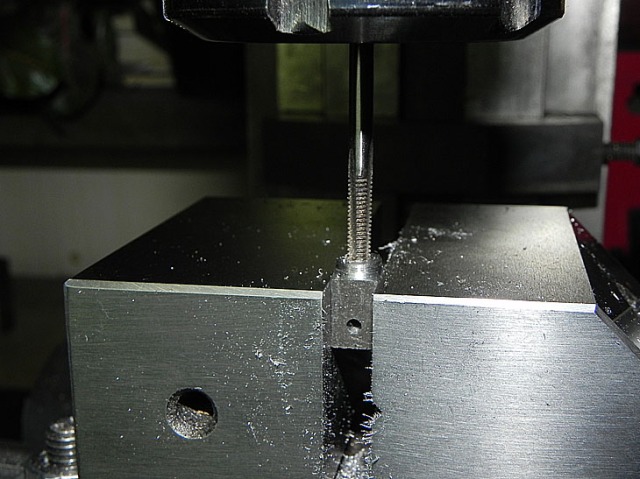

…and threaded the cylinder block with help of a top hat.

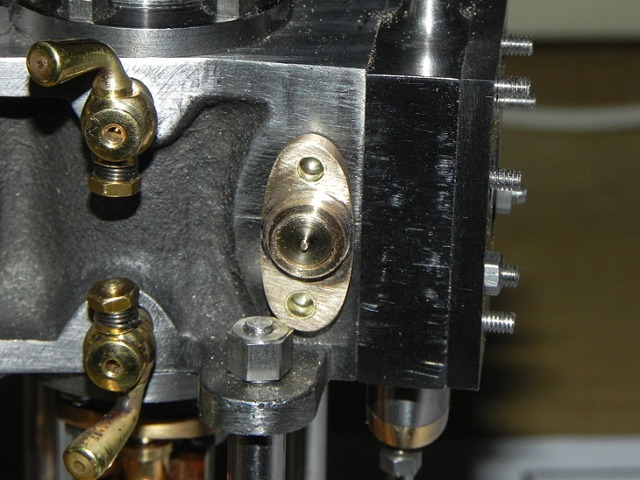

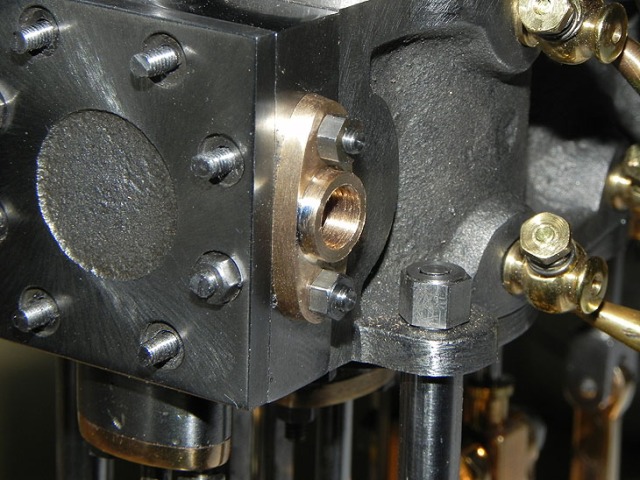

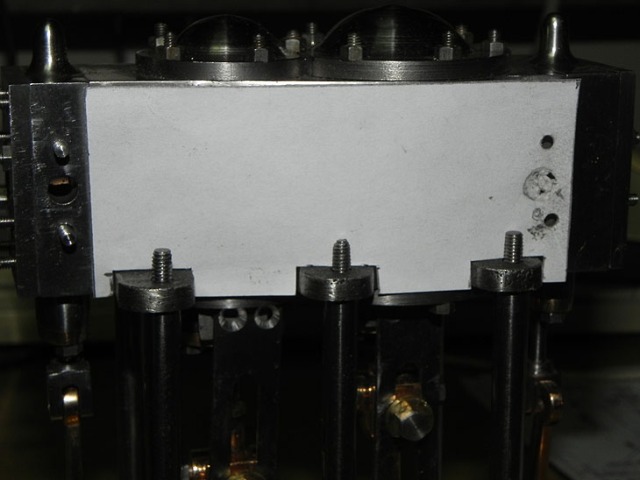

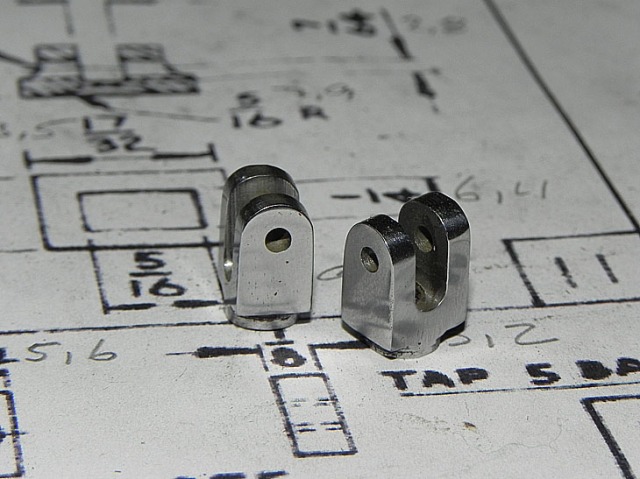

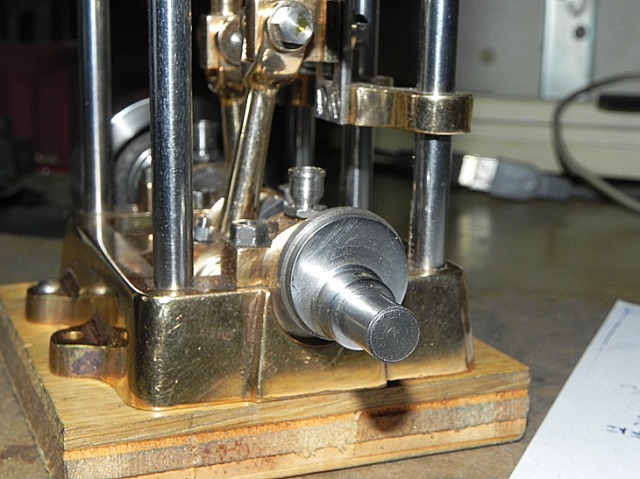

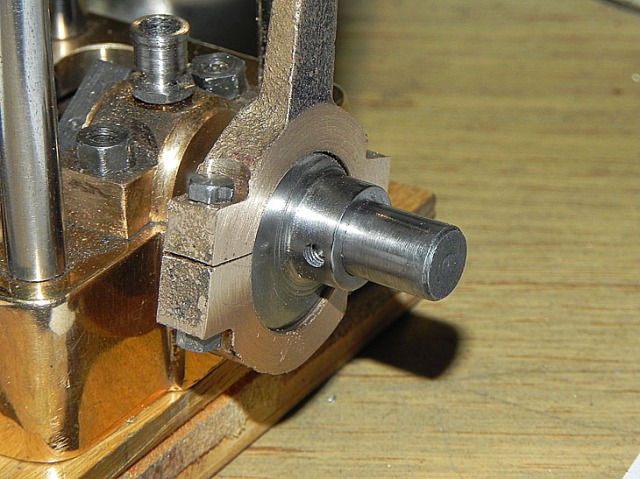

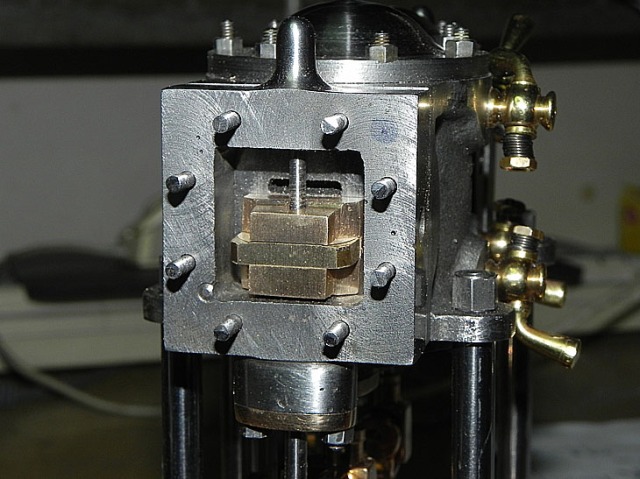

The stem chest with the cover seams to fits very well.

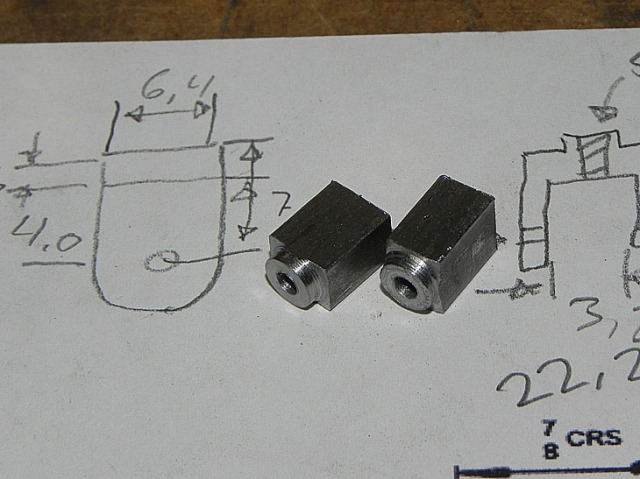

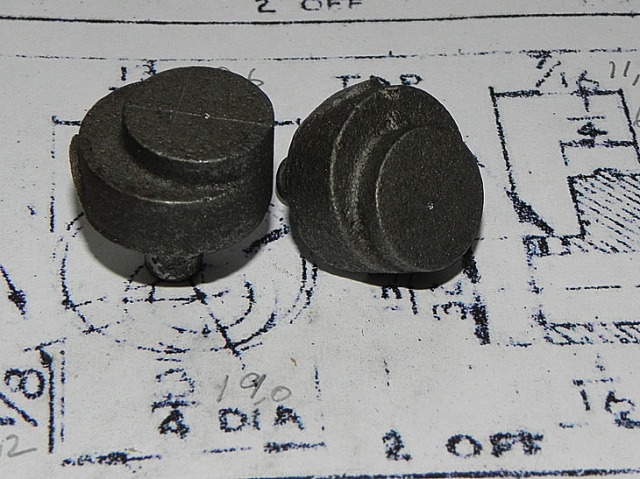

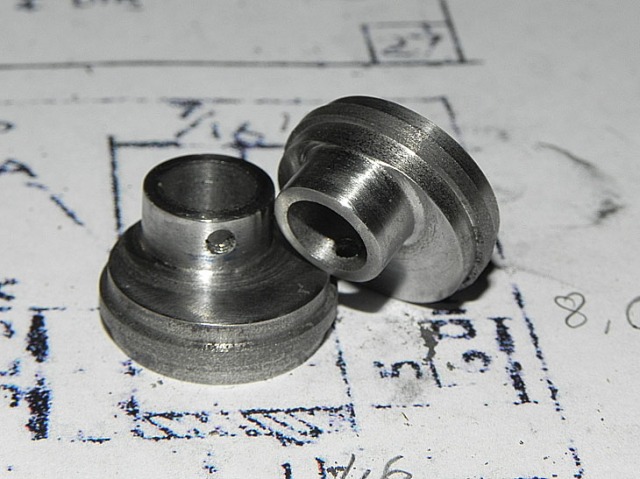

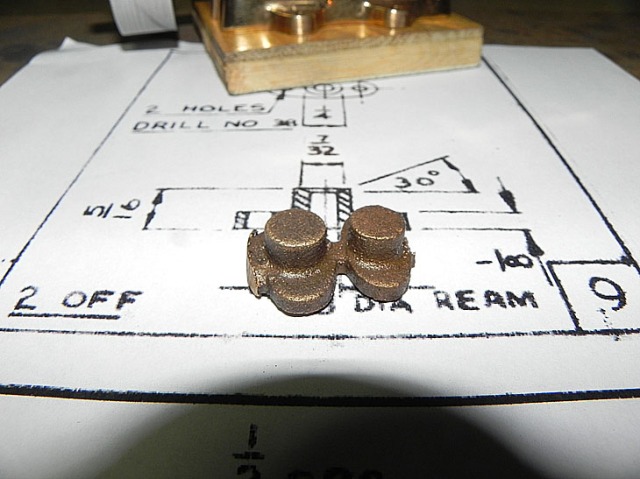

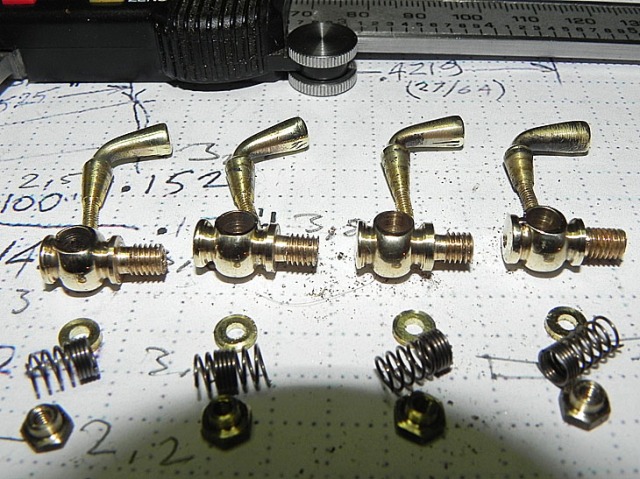

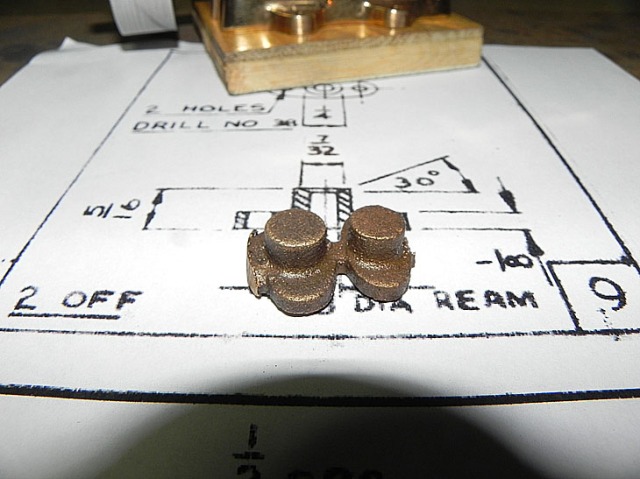

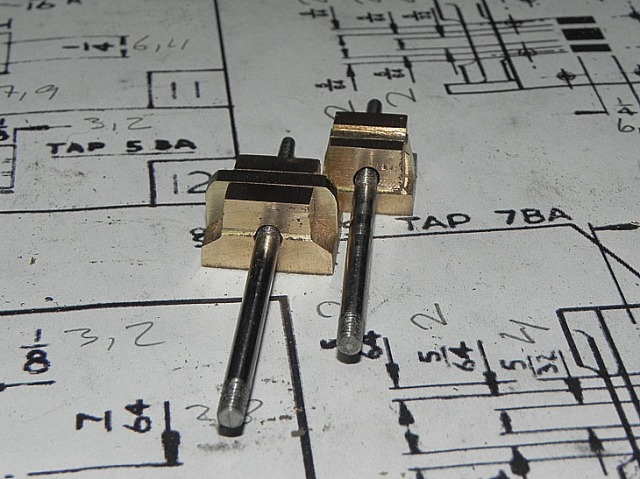

Next, the packing glands.

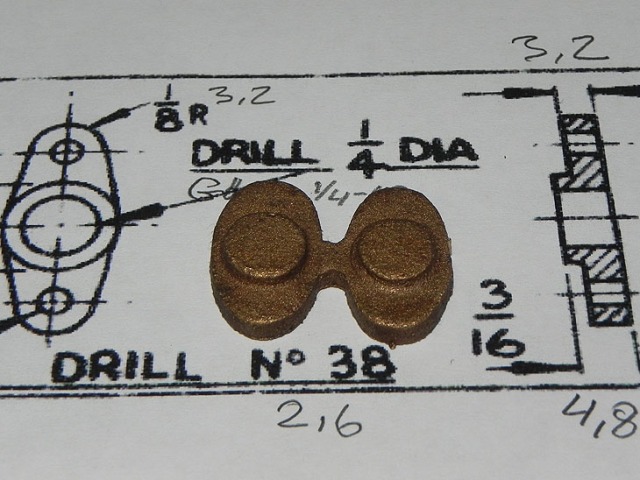

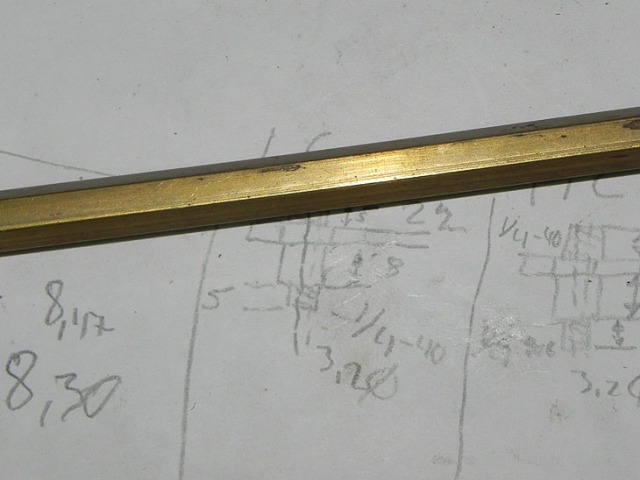

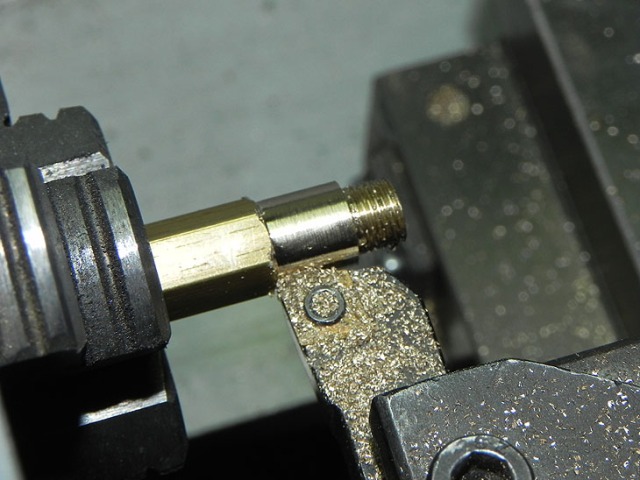

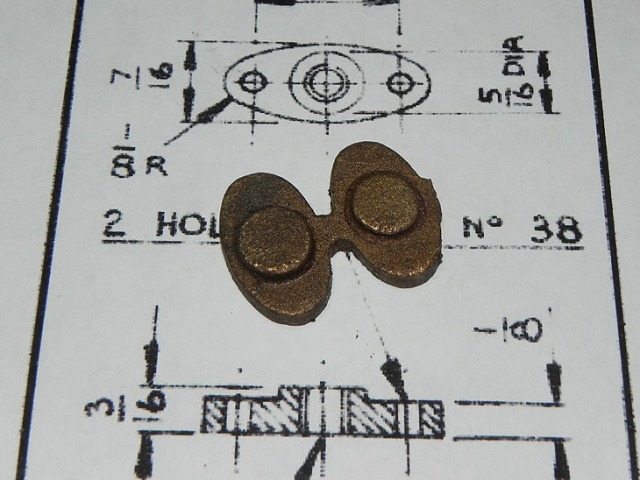

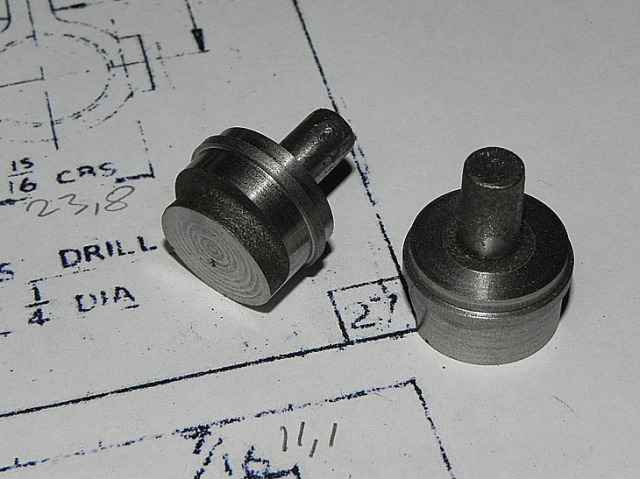

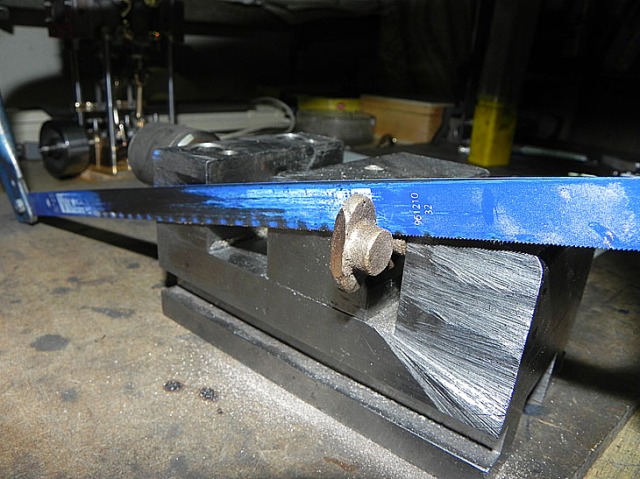

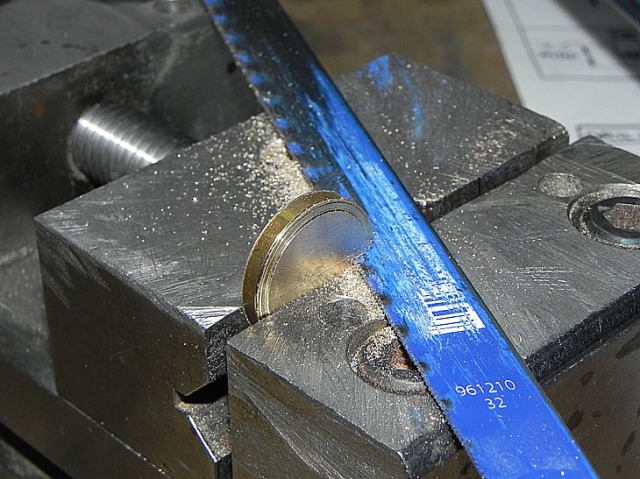

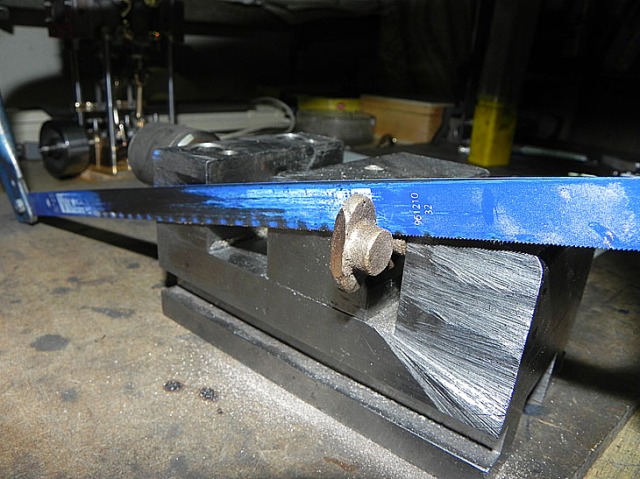

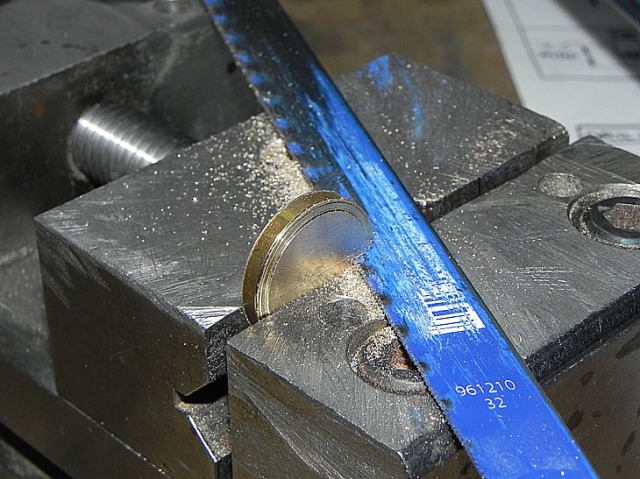

First I have to cutting of the pieces…

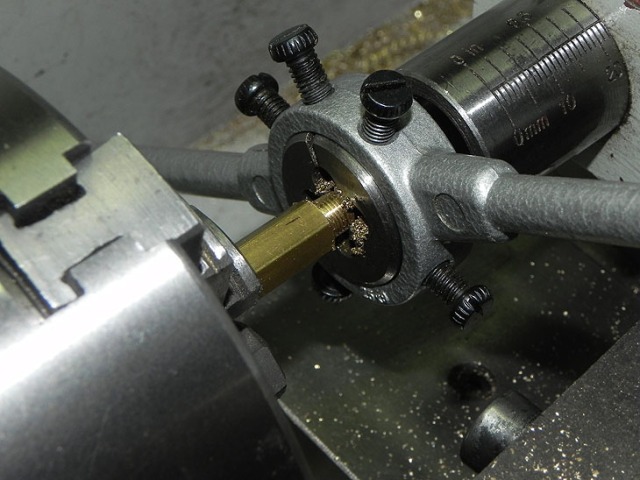

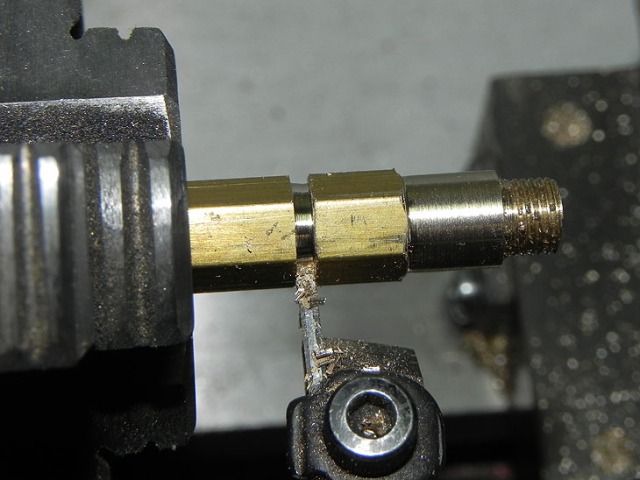

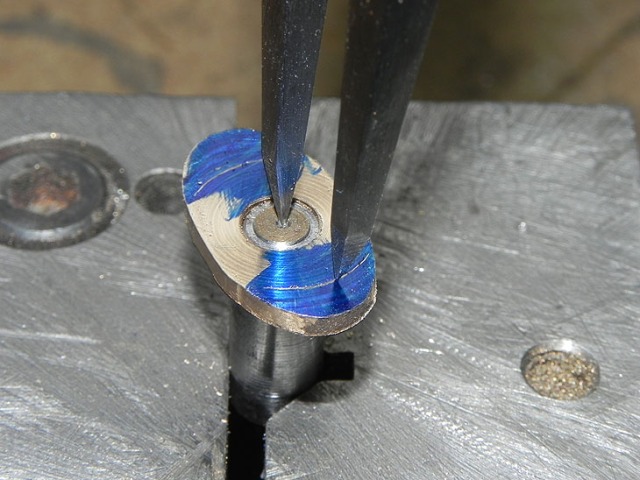

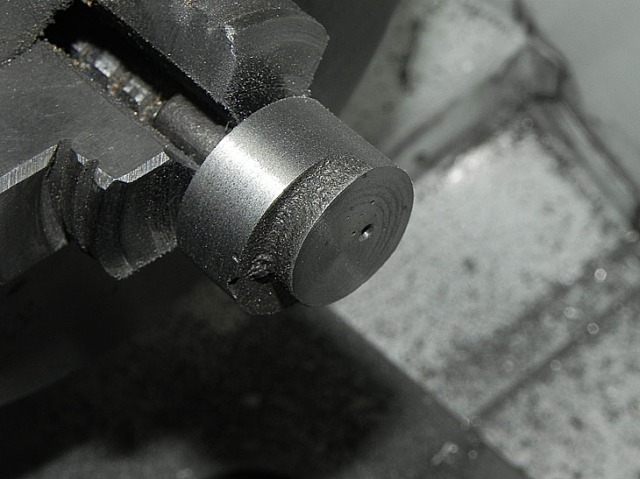

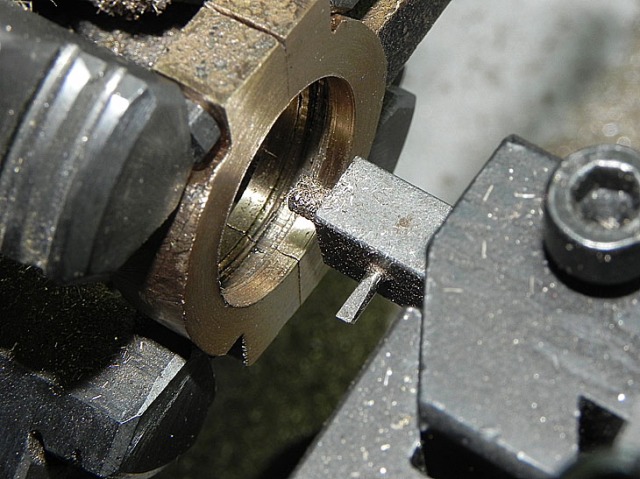

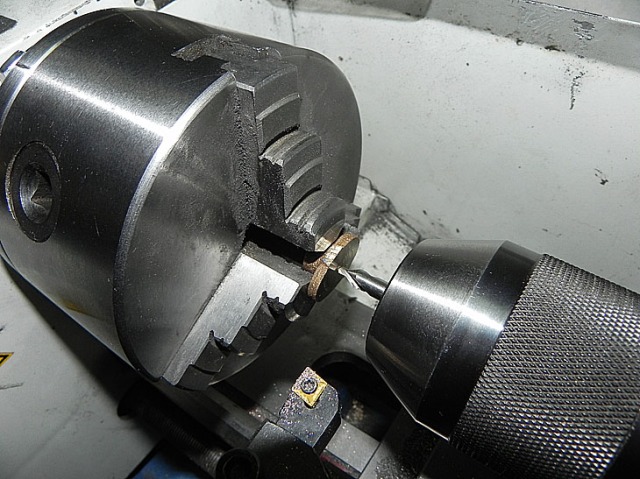

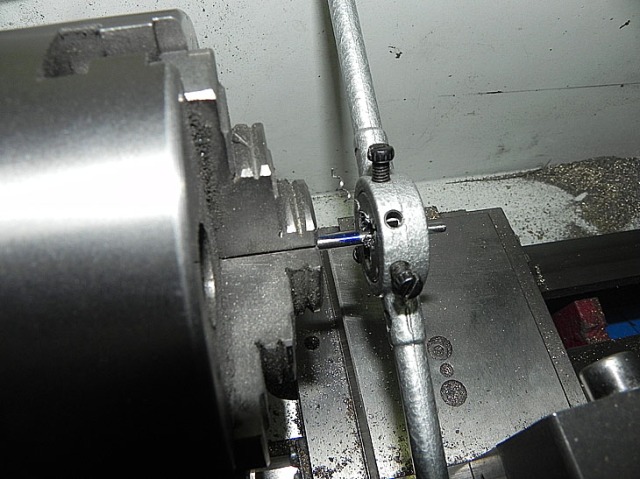

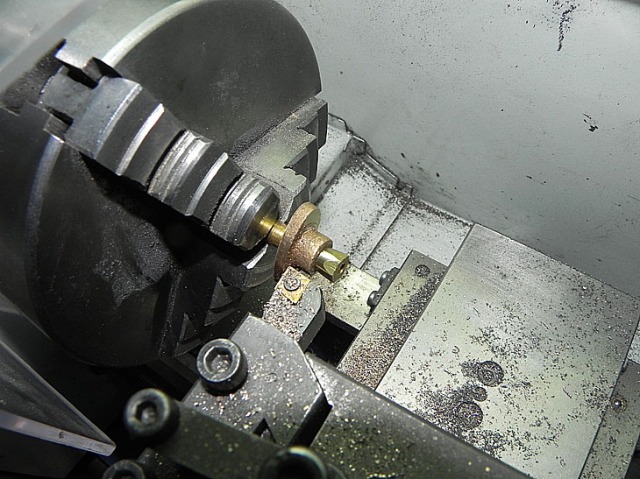

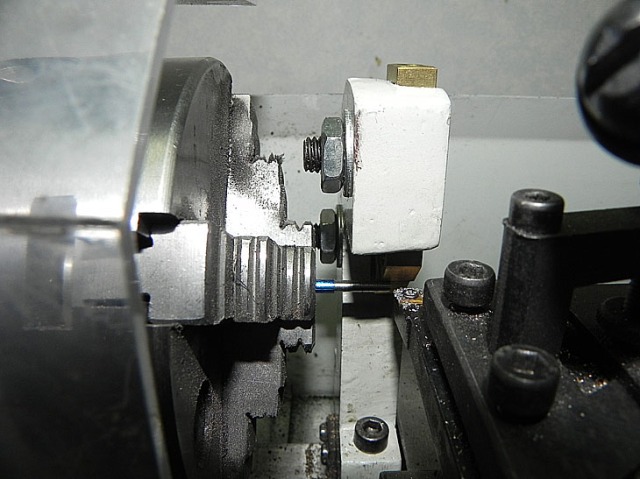

…and the in the lathe for some turns, flatten one side and center drill /drilled a hole.

Then I use a spigot so I could turn the other side.

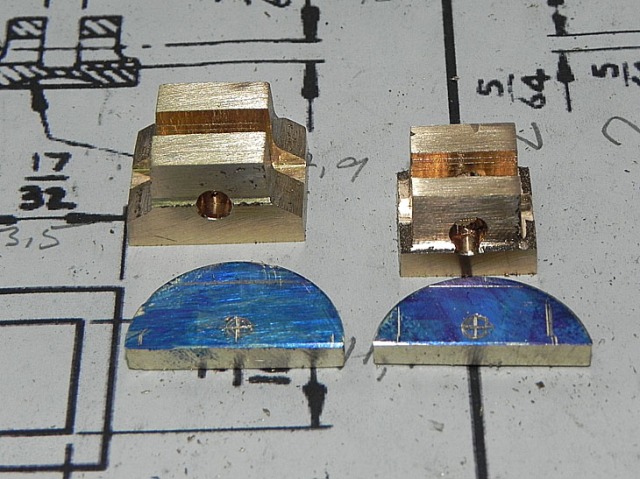

Marking for the holes for the stud, then threaded and then drilling through …

…and after some good work with my fill I have to check so it fits well.

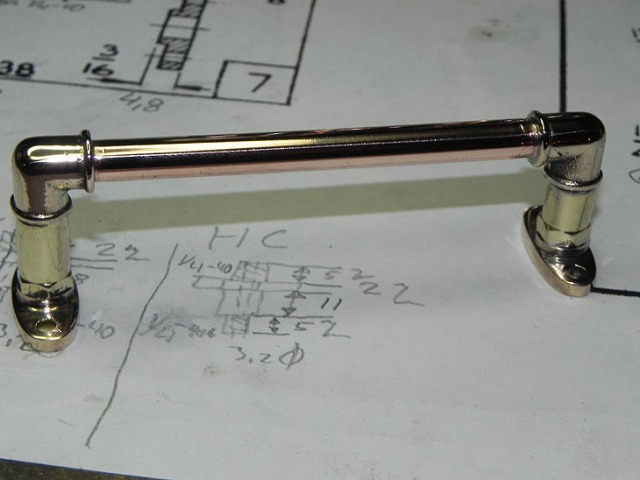

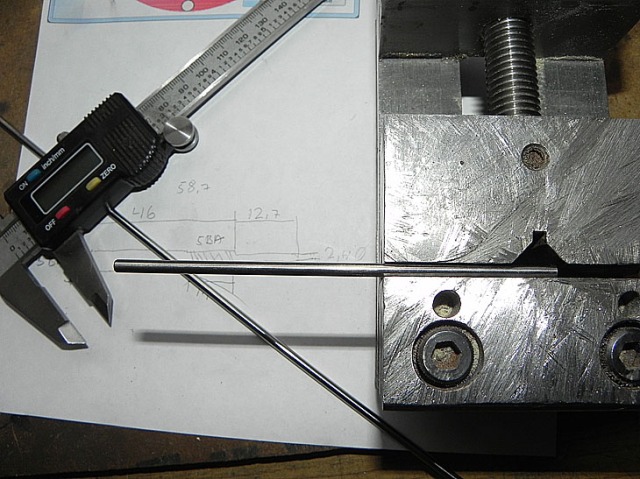

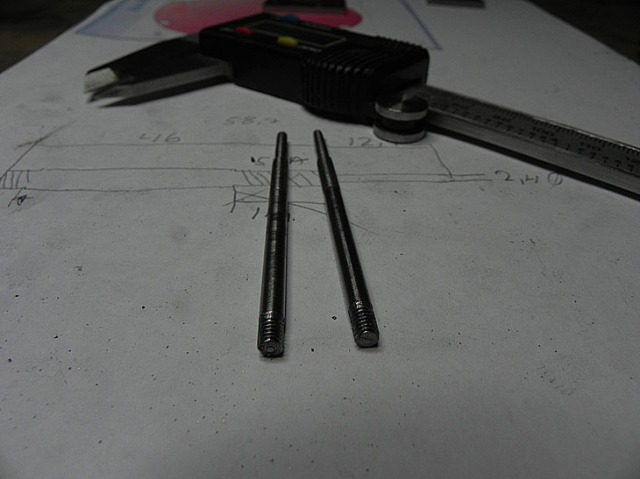

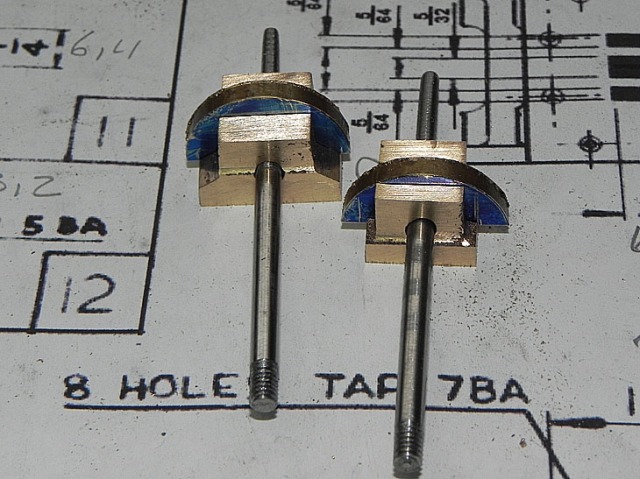

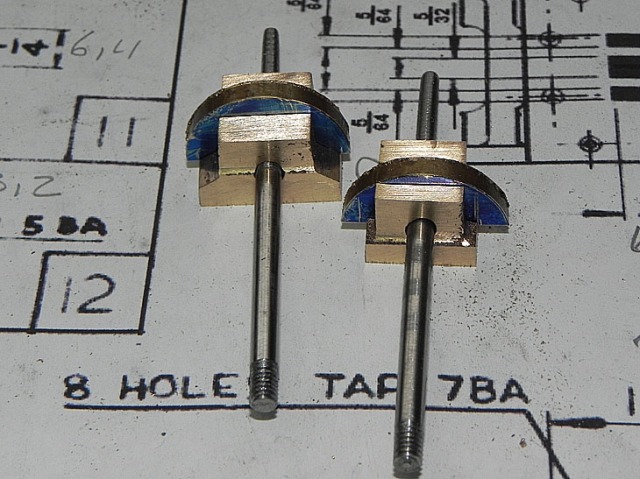

No it’s time for the valve roads.

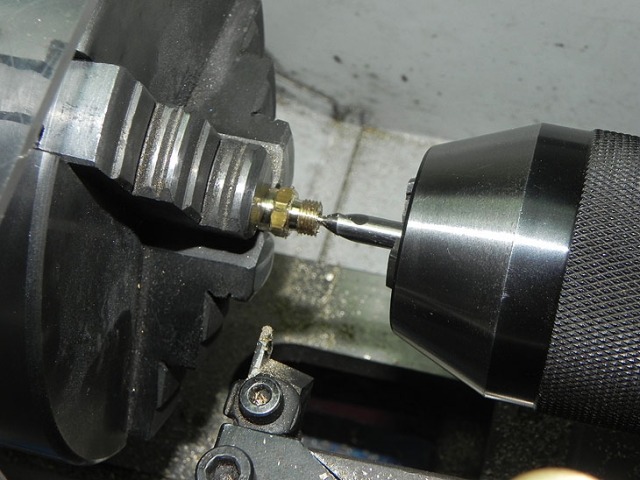

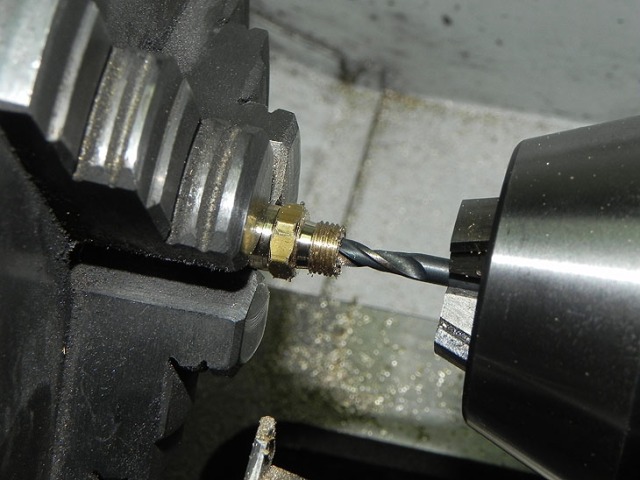

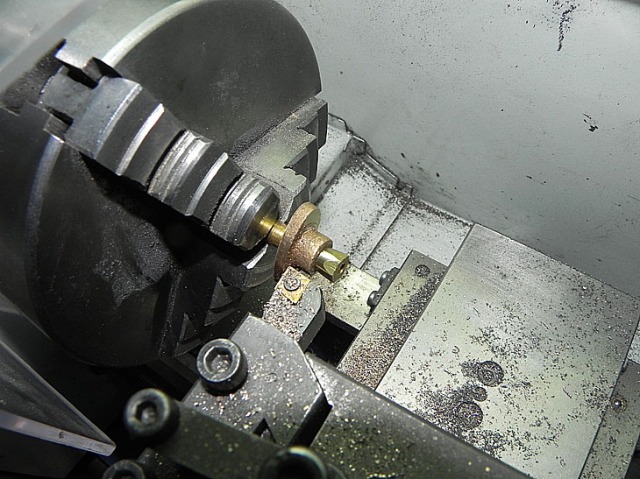

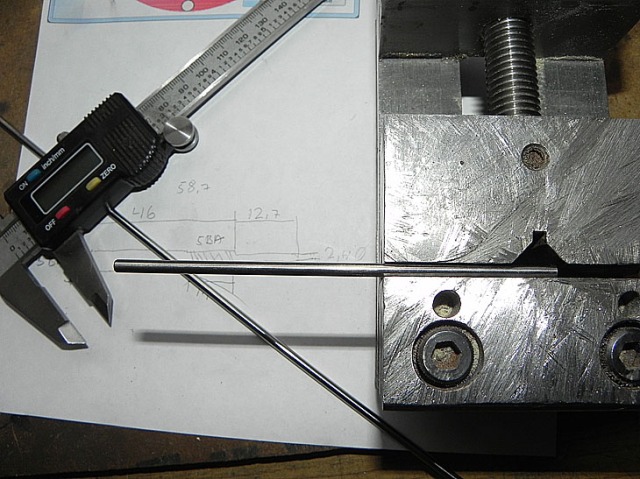

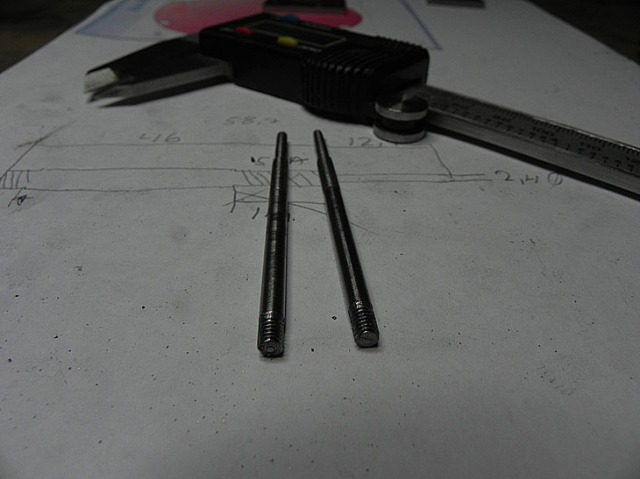

After cutting the parts I took some turn in the lathe and threaded the valve roads …

…in both end.

And now there is to more pieces to the steam chest.

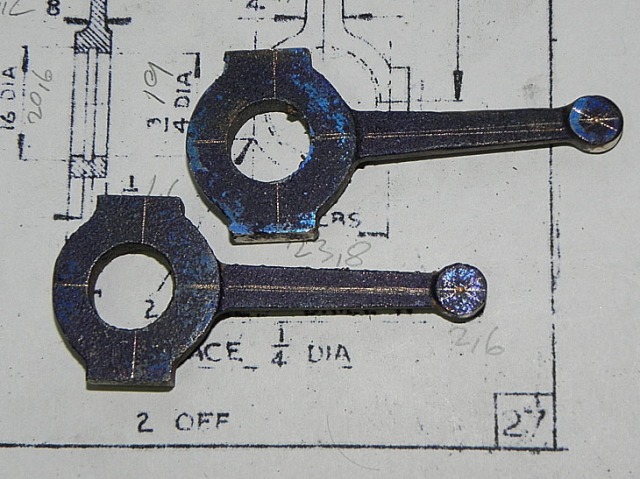

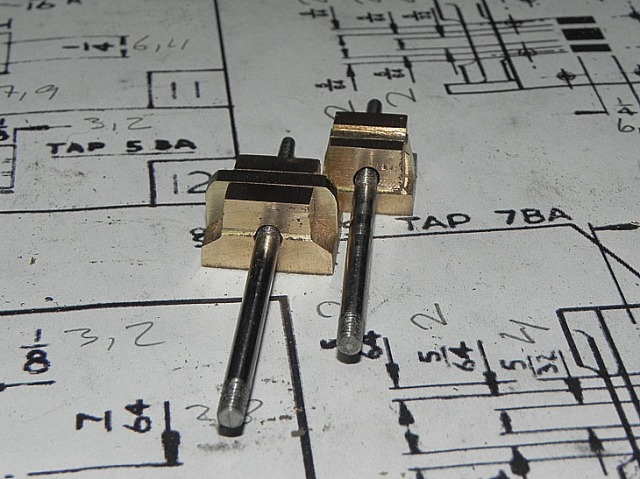

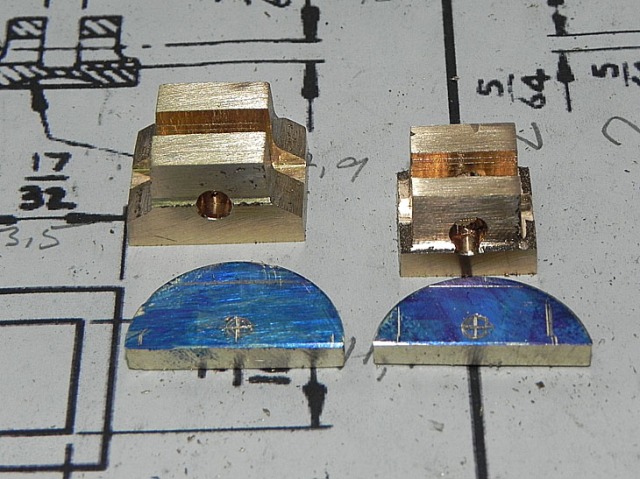

Next, the valve.

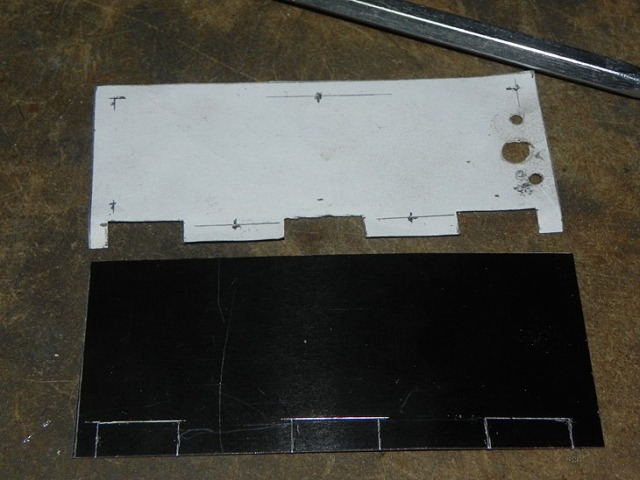

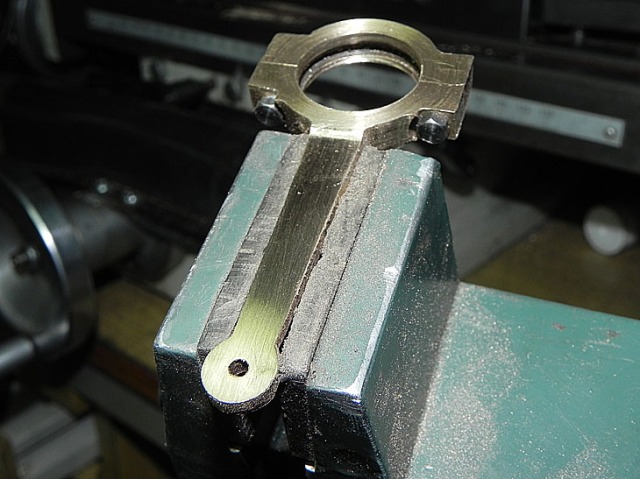

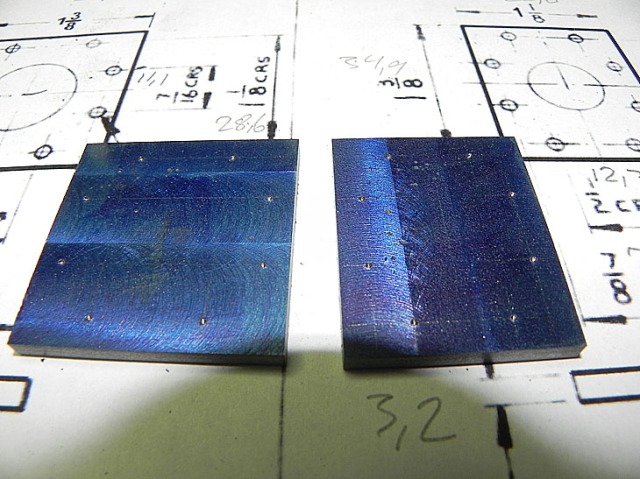

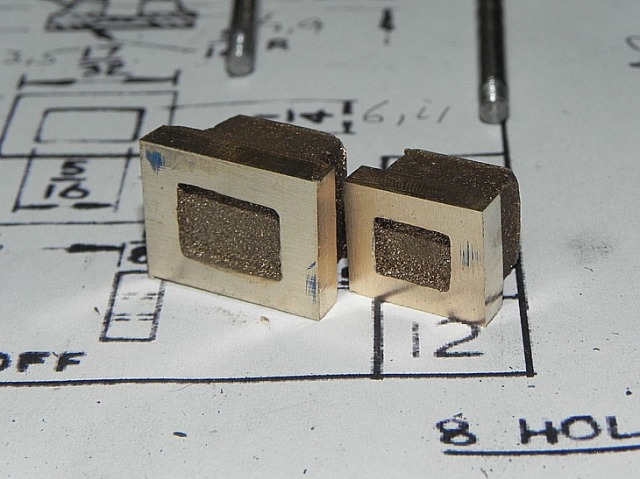

First in the mill I flatted both sides…

…trying to have a smooth side on the valve.

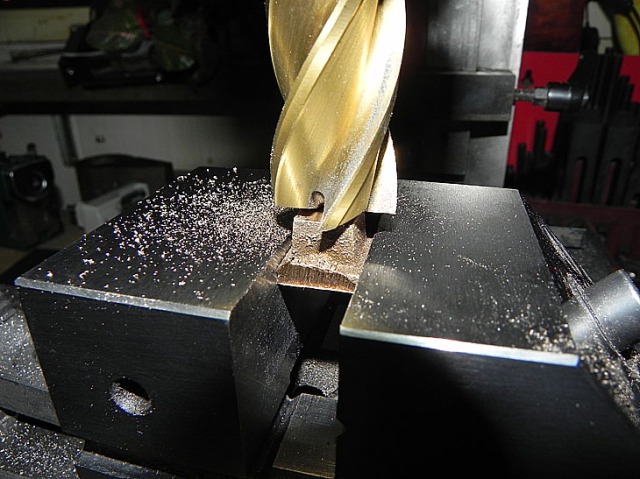

Then drilled throe …

…and then mill a track in the valve.

And now two more pieces finish.

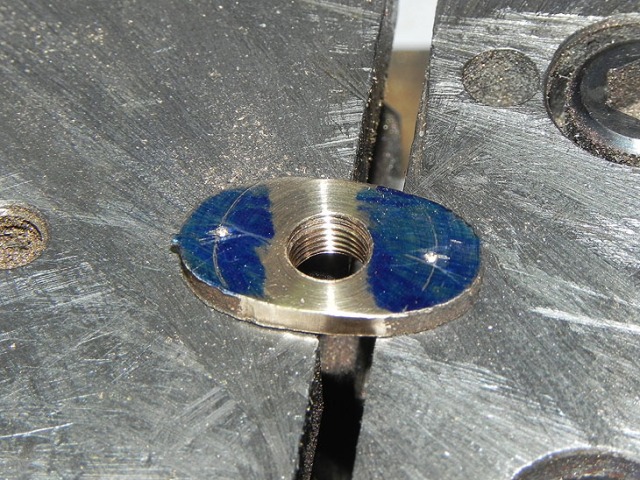

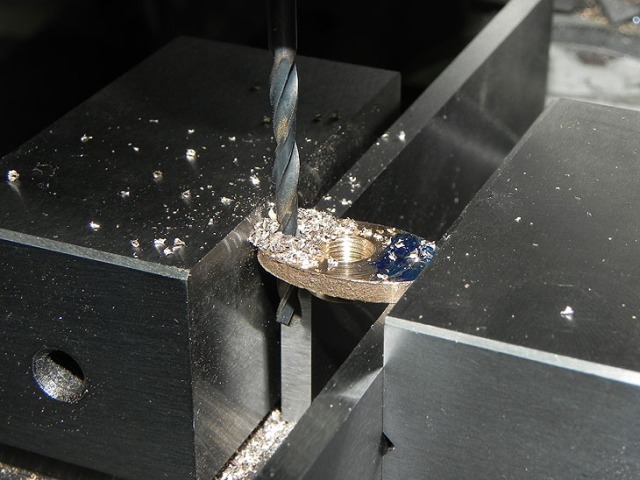

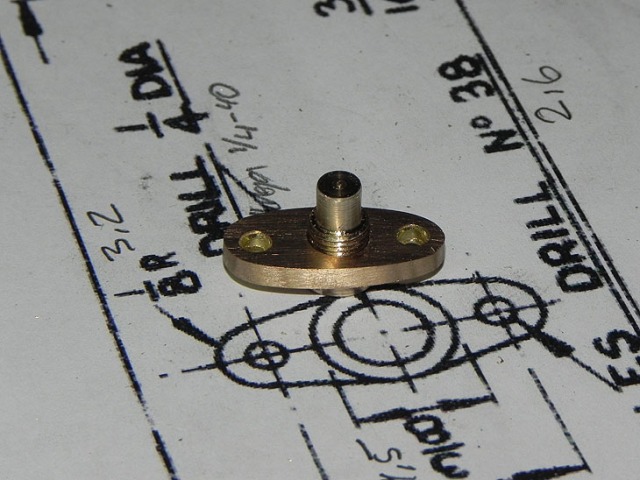

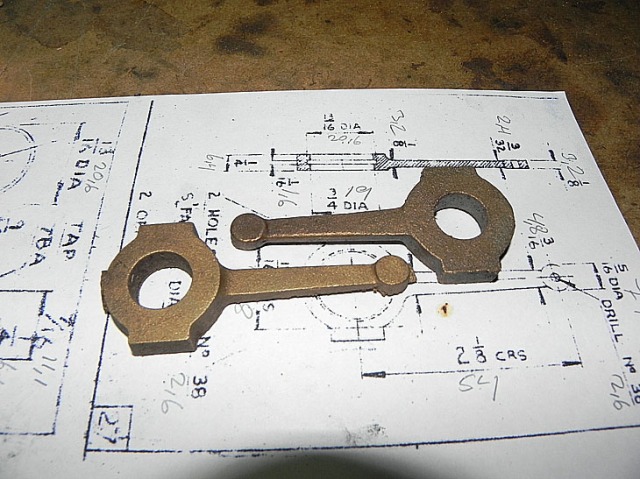

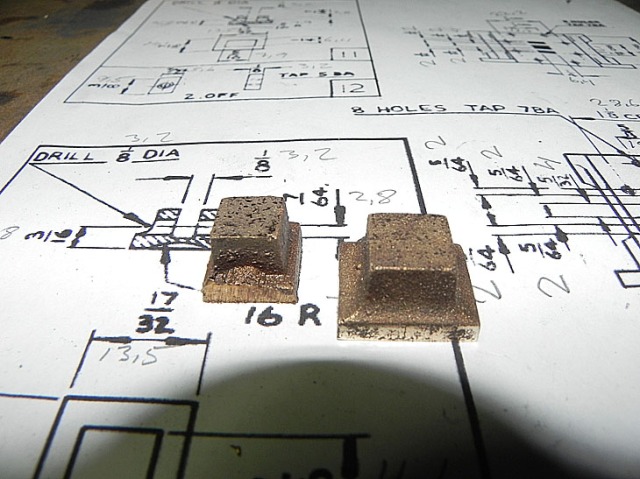

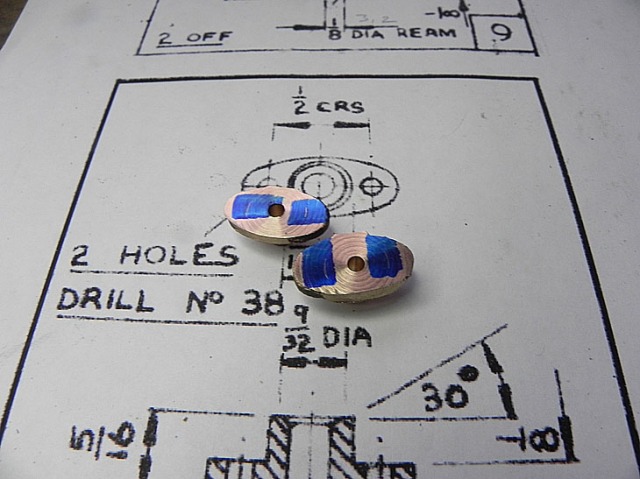

Then I cut of a piece of bras…

…and mark up for a hole to be drilled…

…and threaded…

…and again check for fitting.

Then with a hacksaw and a fill I’ll got this…

…and it fits well in the steam chest.

And now another piece is finish.

This update took some times, it was radar many pieces to make and they have to be accurate, but nothing bad happened so I am very pleased over this update.

I’ll be back.